Understand SAP EWM

2-Step Picking

Note: This post belongs to the blog-series ‘Understand SAP EWM 2-step picking’. The purpose of these series of blog-posts is to explain the concepts of the core features of SAP EWM in a simple way. We want to focus on the basic understanding rather than the smallest details.

As usual, we will go into the real world before we look into the system.

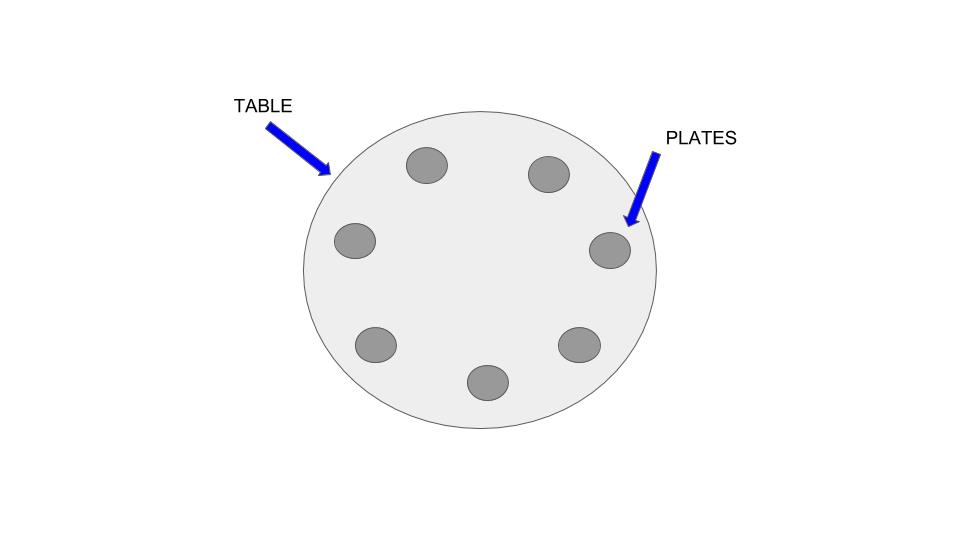

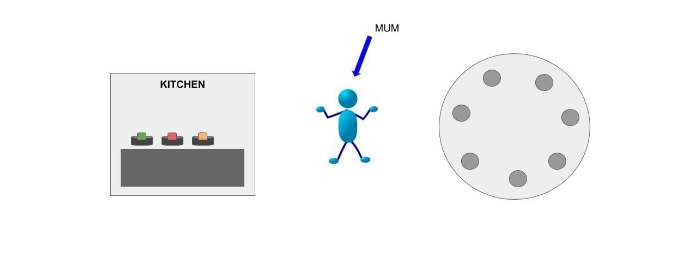

We are sure that most of you have experienced or can still enjoy Sunday afternoon lunch with the whole family at your mother’s place. All your loved ones sitting around a big table, having some good food.

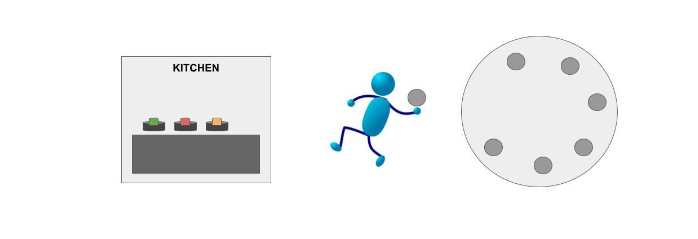

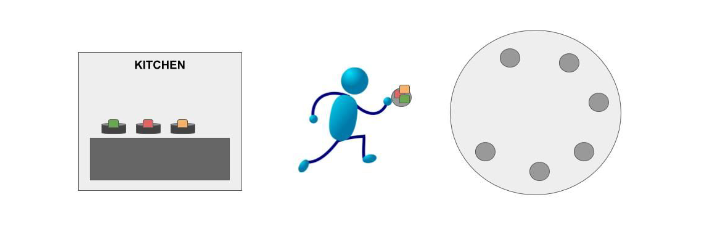

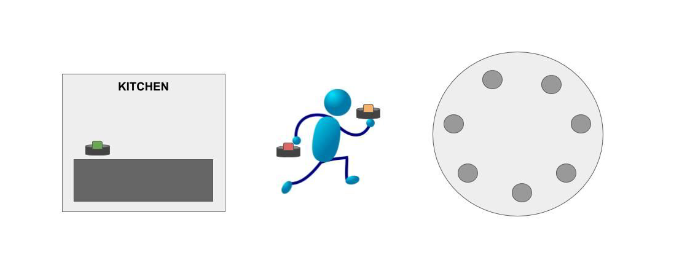

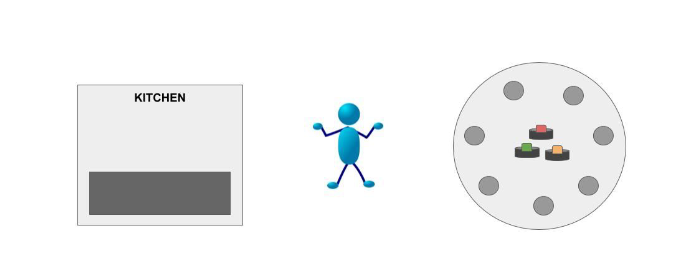

Now imagine the way that the food has to take to get from the kitchen on your plate, banana leaf, bowl or whatever you are using. Usually your mum will not take your sisters plate fill it in the kitchen with all the components of the lunch, walk back to the living room, bring it to your sisters place at the table and to the same thing for everybody else.

To sum it up from process perspective –

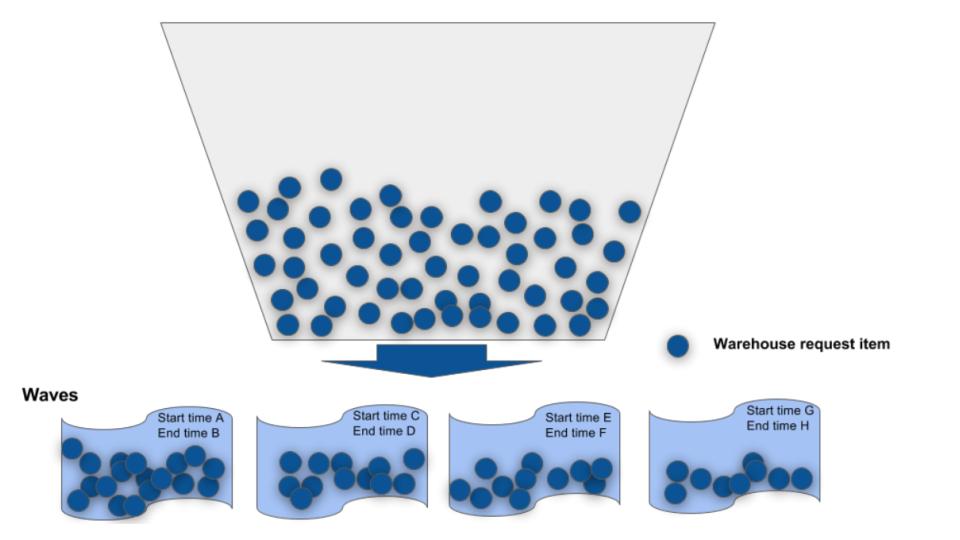

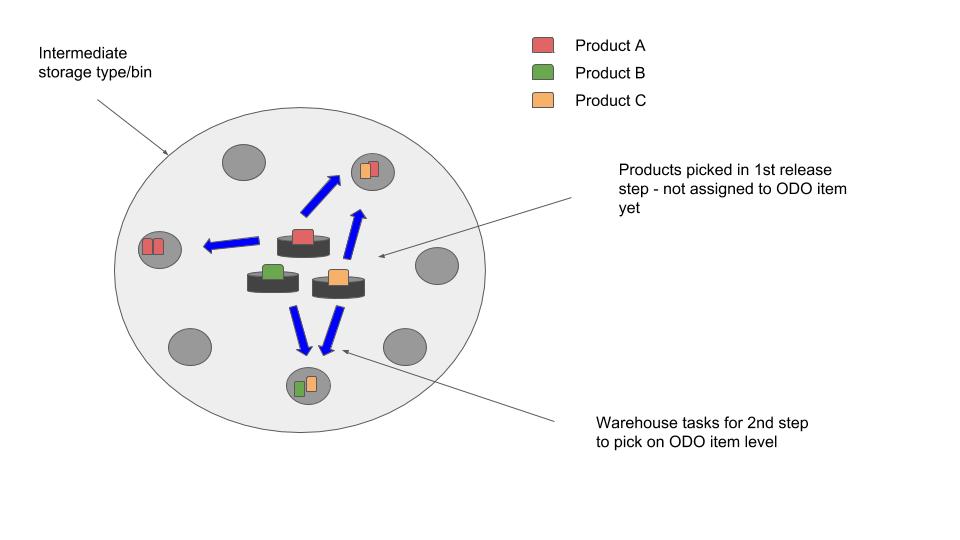

We optimize the picking by collectively removing products which are requested by multiple different ODO items. This way we minimize the picking operations and reduce the total travel distance.

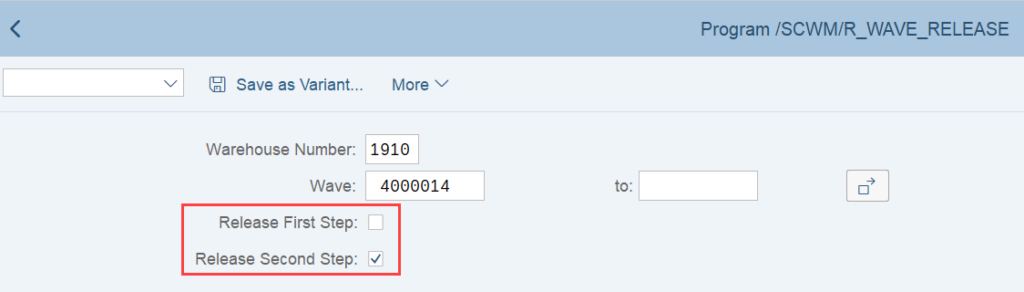

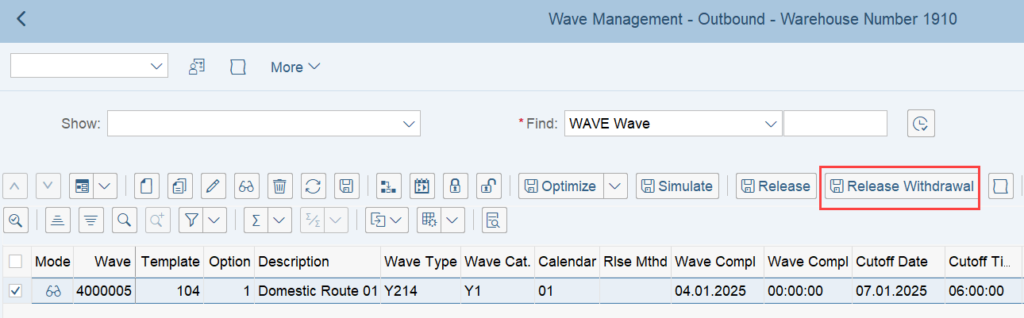

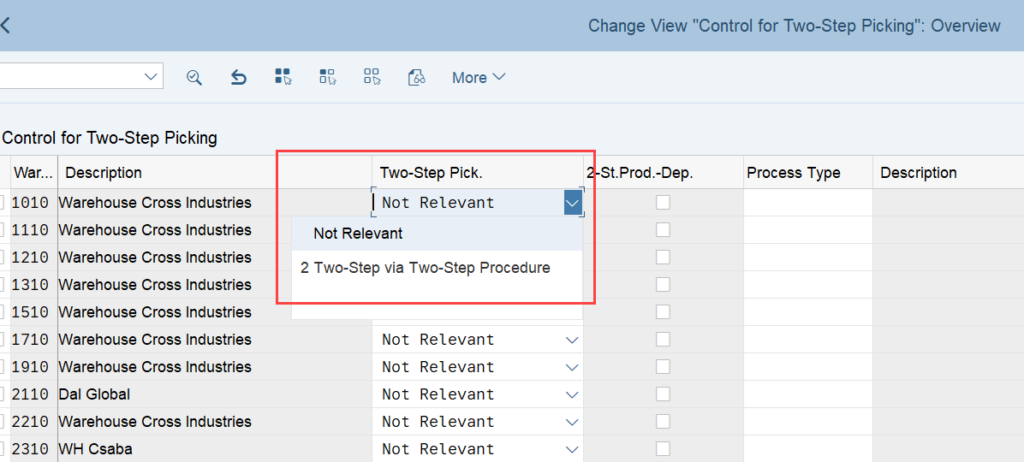

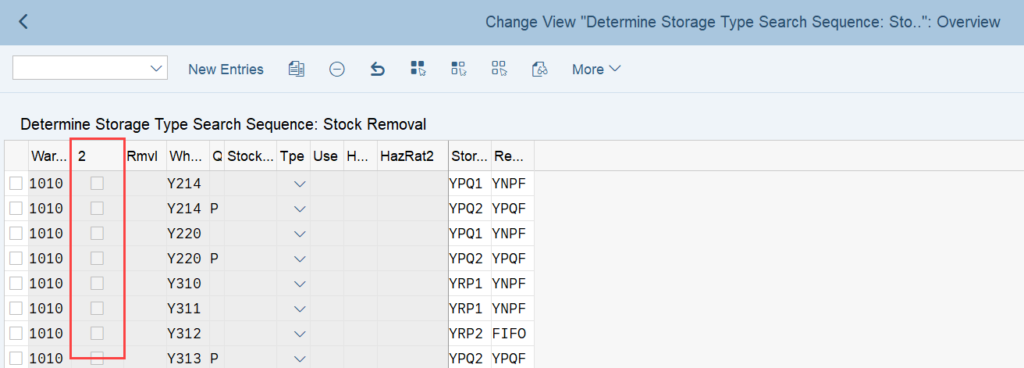

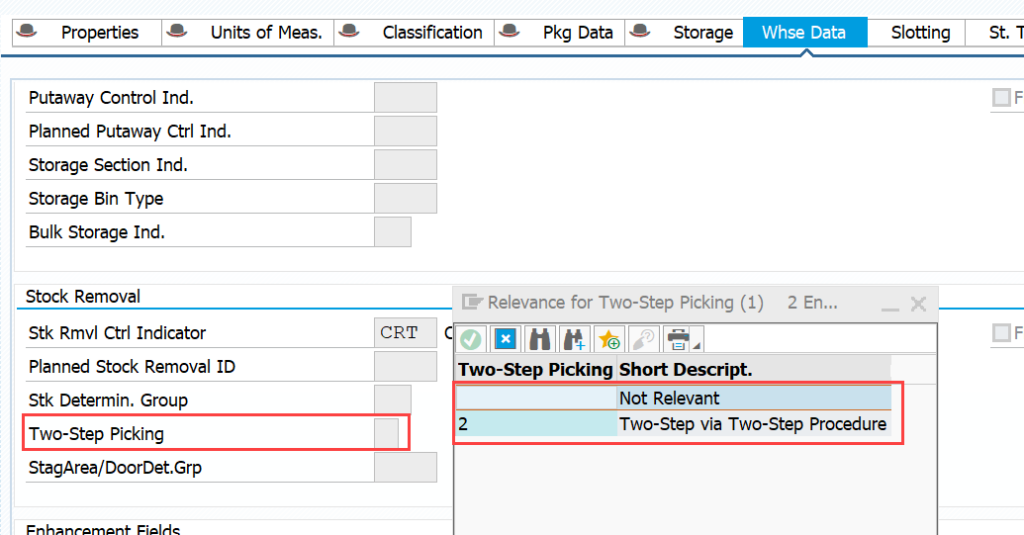

The customizing is pretty straightforward here. Just a quick look as the purpose of this video is not to guide you through the implementation.

Apart from types & bins for intermediate storage you need to activate 2-step picking on warehouse level and assign a warehouse process type for the withdrawal step. In addition you need a dedicated storage type search sequence for the withdrawal step. This record is looking at the initial source bin. An additional record needs the intermediate storage type as a source bin to help creating the final warehouse task for the distribution from the intermediate bin.

I hope this blog post provides value to you and you could learn something. Please feel free to subscribe to my blog updates or my youtube channel in case you want to be notified about new posts!