Understand SAP EWM

Pick & Pass

Note: This post belongs to the blog-series ‘Understand SAP EWM’. The purpose of these series of blog-posts is to explain the concepts of the core features of SAP EWM pick & pass in a simple way. We want to focus on the basic understanding rather than the smallest details.

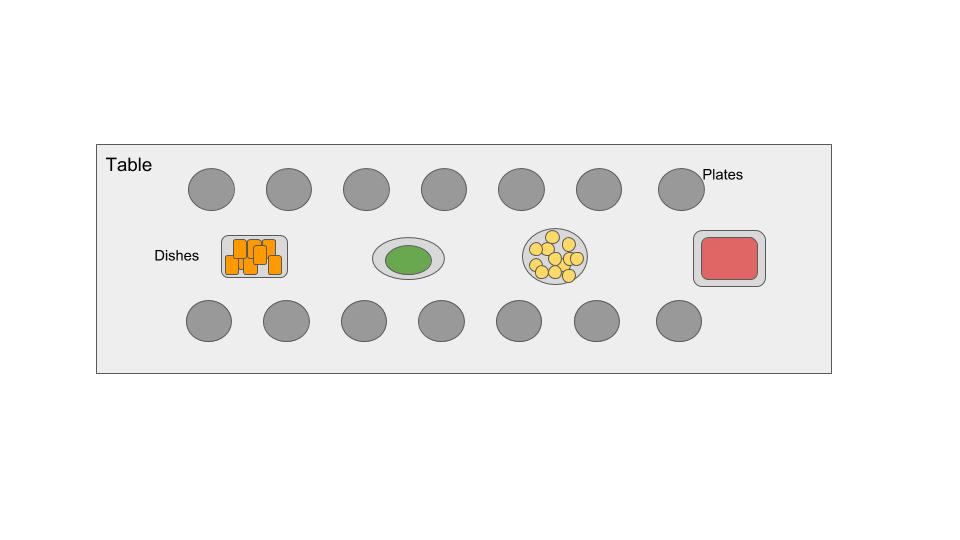

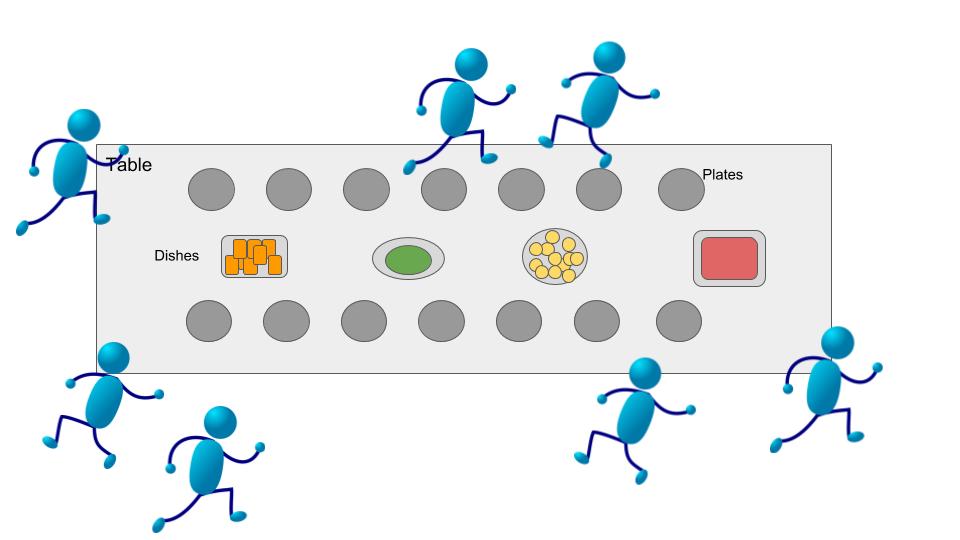

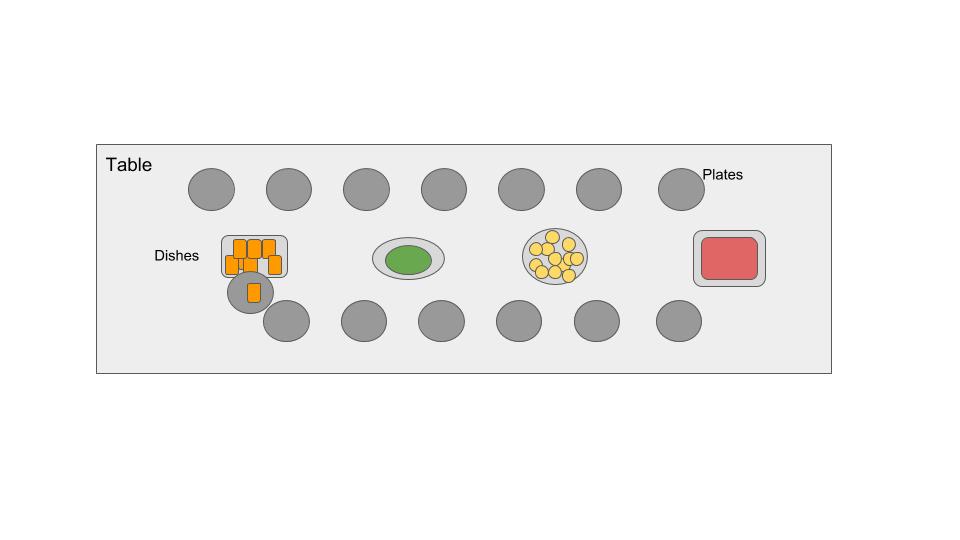

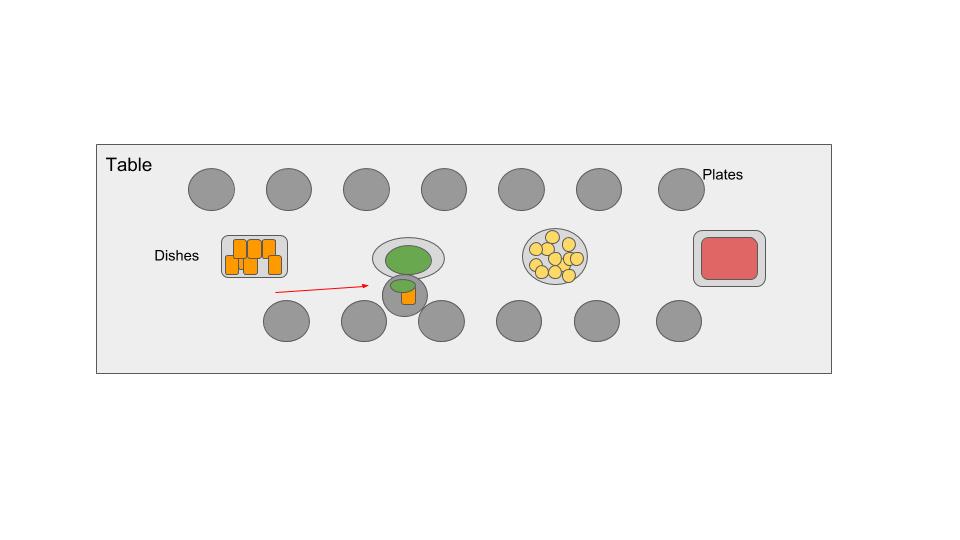

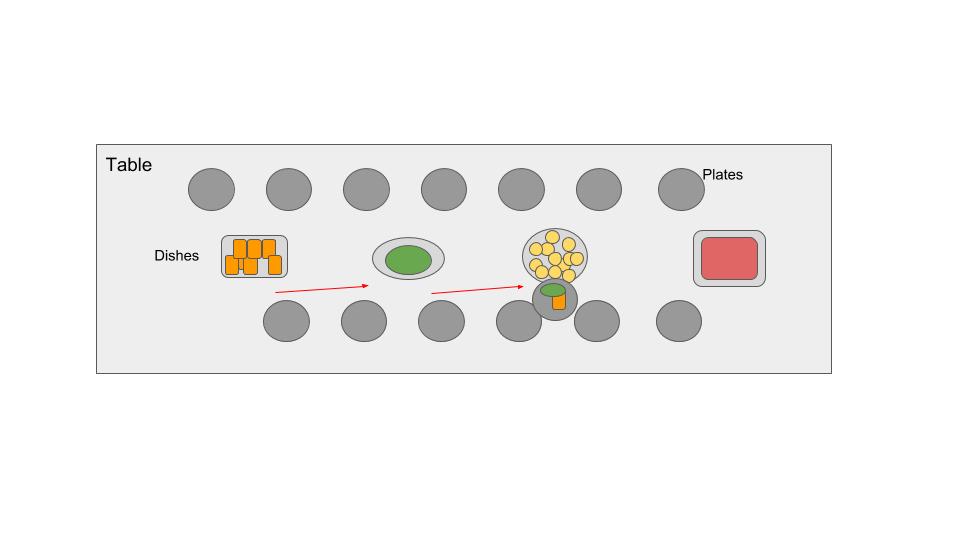

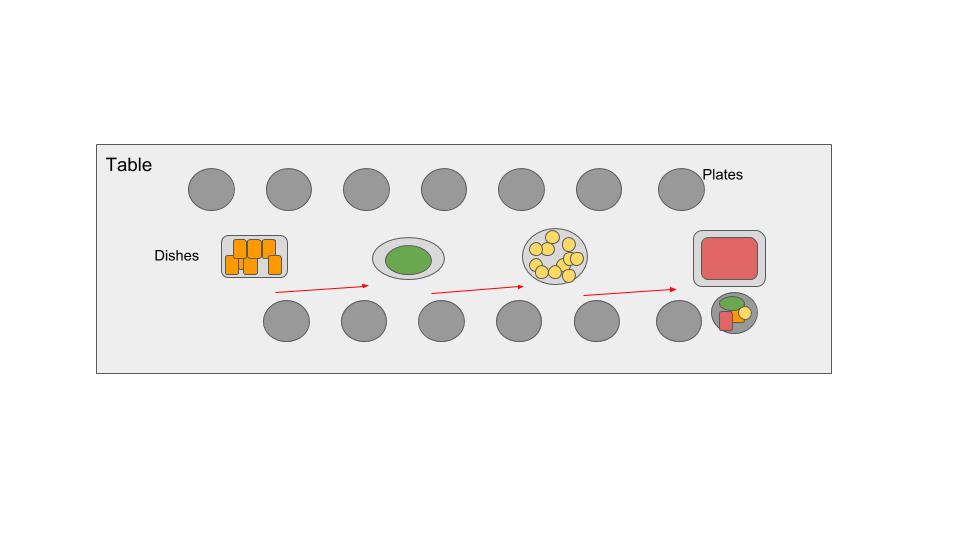

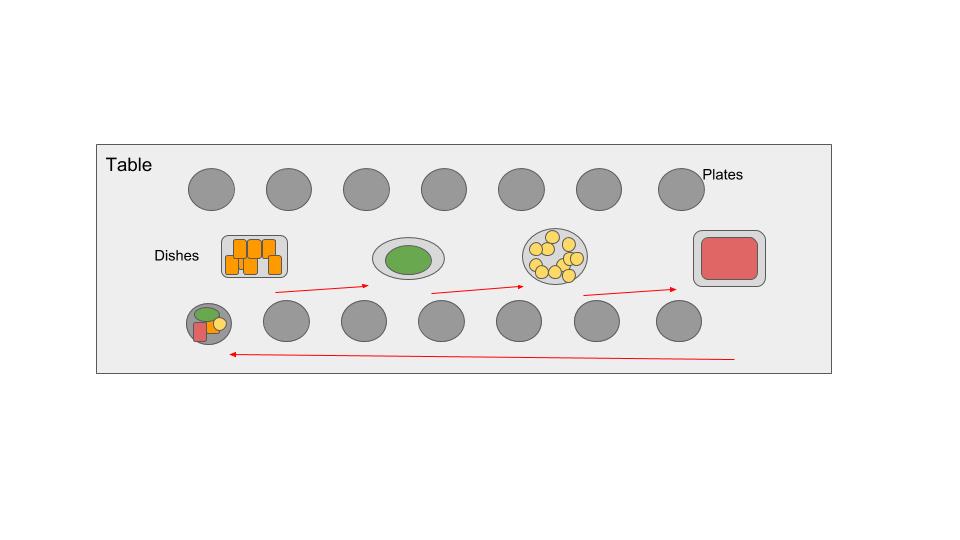

As usual, we start with an example from the real world. You might remember one blog article where we have been talking about the Sunday afternoon dinner with the whole family. Imagine the family (and so the table) a little bit bigger now and different kind of dishes placed all over the table. Everybody wants his/her plate to be filled with samples from all those dishes but if everybody fills the plate by himself/herself. It will be a chaotic having everybody running around the table.

OK – I think you see where we are looking at. So let’s jump into warehouse logistics now.

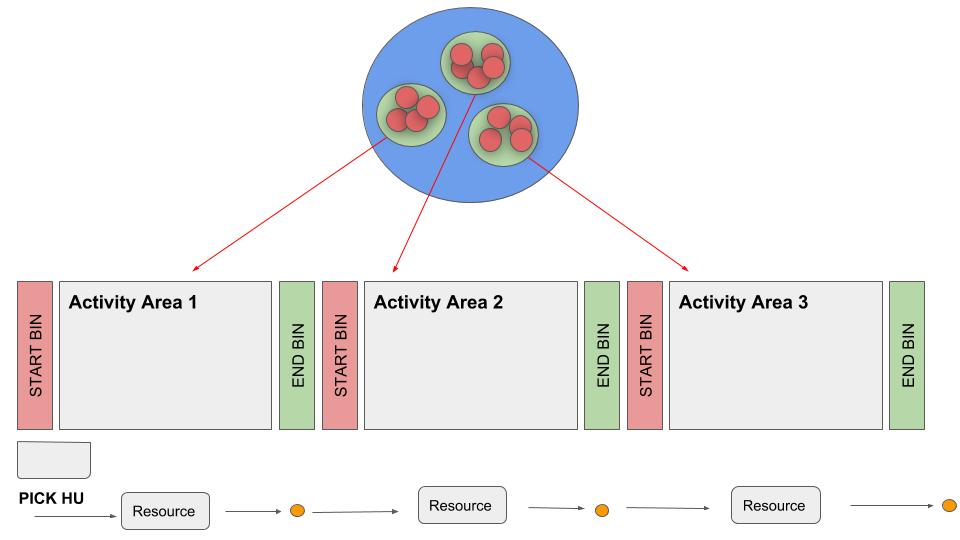

Imagine a large warehouse where you must pick lots of orders with small quantities of many different products. These products are stored in different areas of the warehouse. Those areas (which we will call ‘zones’ in the following minutes) can (or should) not be served by the same resource (e.g. because the distance is too long or in the different zones you have to use different equipment).

Now you have two options to execute the picking process:

- Option 1: Pick from the different zones into different pick-HUs and consolidate those HUs at a work center in the packing or staging area

- Option 2: First pick from one zone and then handover to the next zone (so basically consolidate into one pick HU during picking already). This is what we call ‘Pick & Pass’ in EWM

There are different factors/criteria to decide which way to go but this decision process should not be part of this video. We will rather concentrate on how the 2nd option works.

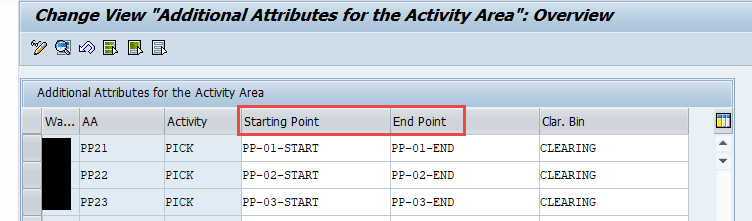

Assume in our example picking is done manually from a rack and the transfer between the different zones is enabled by a conveyor system. This is probably the most common approach whereas the transfer can also be done by a manual transport from the given end point to the next starting point.

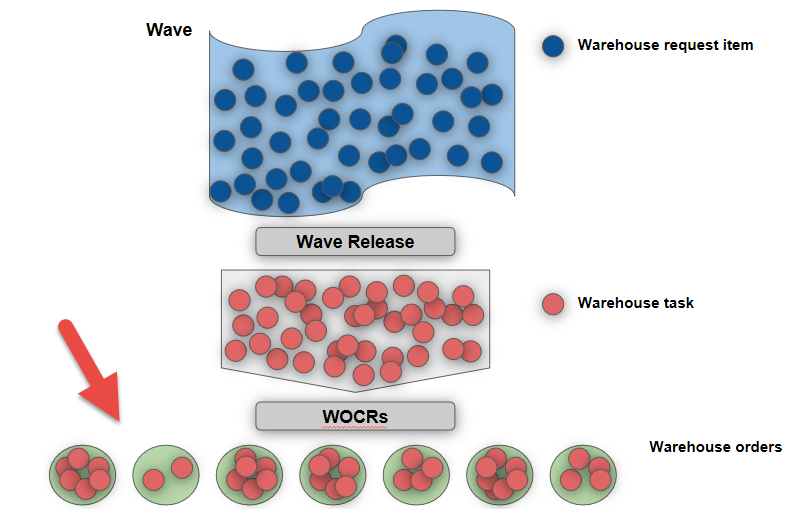

Before we investigate the system setups, we will describe the main components which are needed to conduct a pick & pass process in EWM

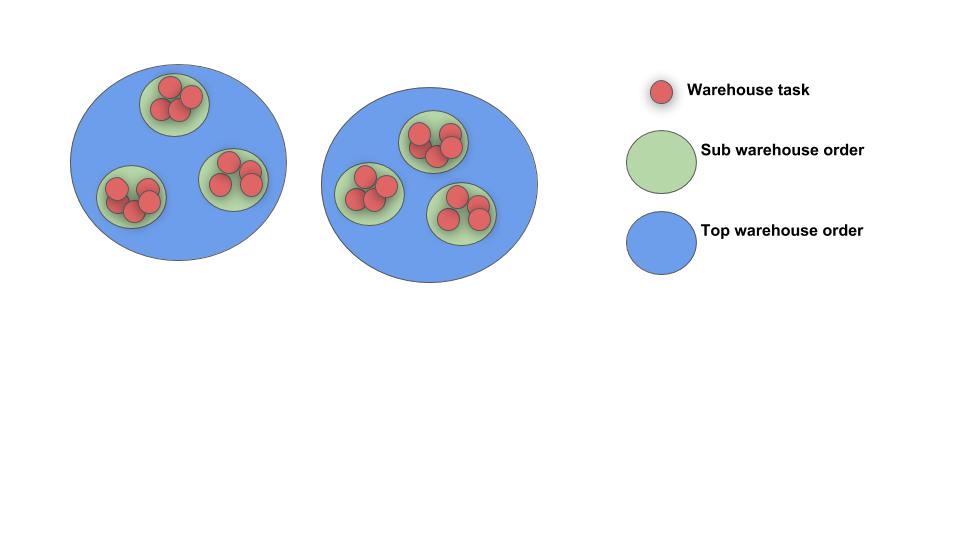

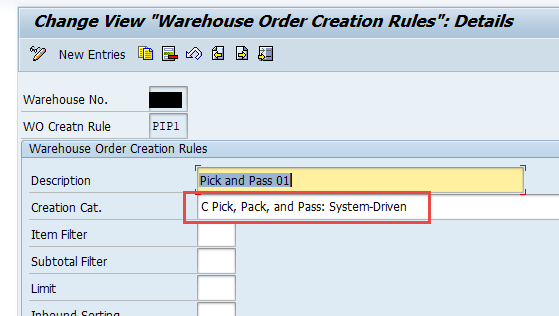

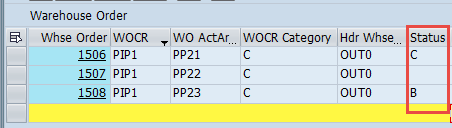

First of all, we have two different kind of warehouse orders. ‘Normal’ warehouse orders for each zone having the warehouse tasks assigned to it.

‘Top’ warehouse orders which group together all ‘normal’ warehouse orders which have been created for the different zones:

System setup –

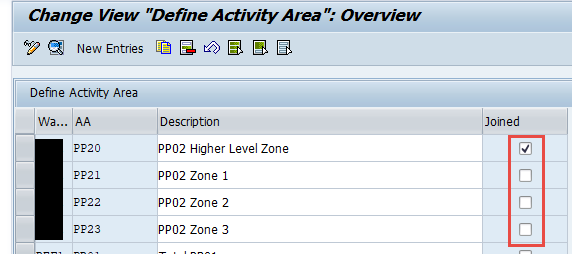

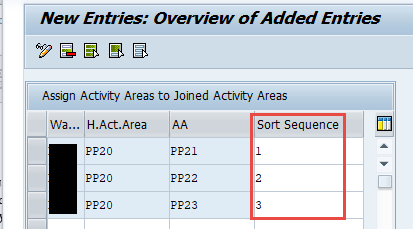

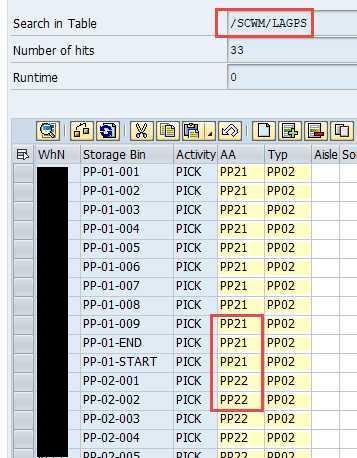

Let us have a quick look at the most important point regarding the system setup. At first, we must create activity areas and join them. I do assume that you know what an activity area is and how it can be setup. The only thing you need to do (apart from setting up one AA for each zone) is to join and sort all those activity areas which should be part of one pick & pass run later:

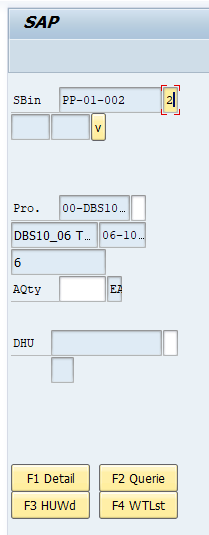

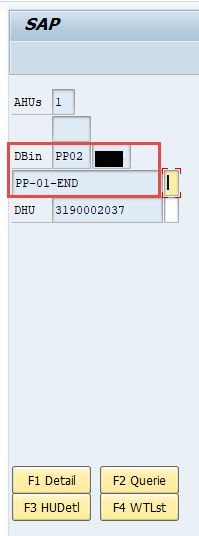

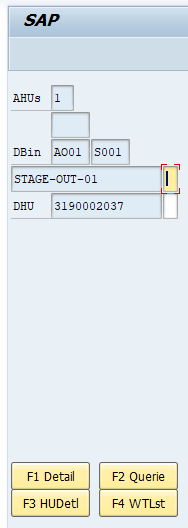

The picking process itself from operator perspective is not different from picking non-joined warehouse orders. The only difference is the screen to handover to the next zone which will be displayed once all warehouse tasks for a given sub warehouse order have been completed:

That’s it!

I hope that helps especially the beginners among you to understand the concept. For the experts please excuse me not to dig into all details and configuration options as the communication of those things is not the objective of this video and can be taken from SAP books or customizing documentation, if needed.

I hope this blog post provides value to you and you could learn something. Please feel free to subscribe to my blog updates or my youtube channel in case you want to be notified about new posts!