Understand SAP EWM

The purpose of wave management & resource management

Note: This post belongs to the blog-series ‘Understand SAP EWM the purpose of wave management & resource management in SAP EWM’. The purpose of these series of blog-posts is to explain the concept of the core features of SAP EWM in a simple way. It is intended to target EWM beginners and focuses on the basic understanding rather than the smallest details.

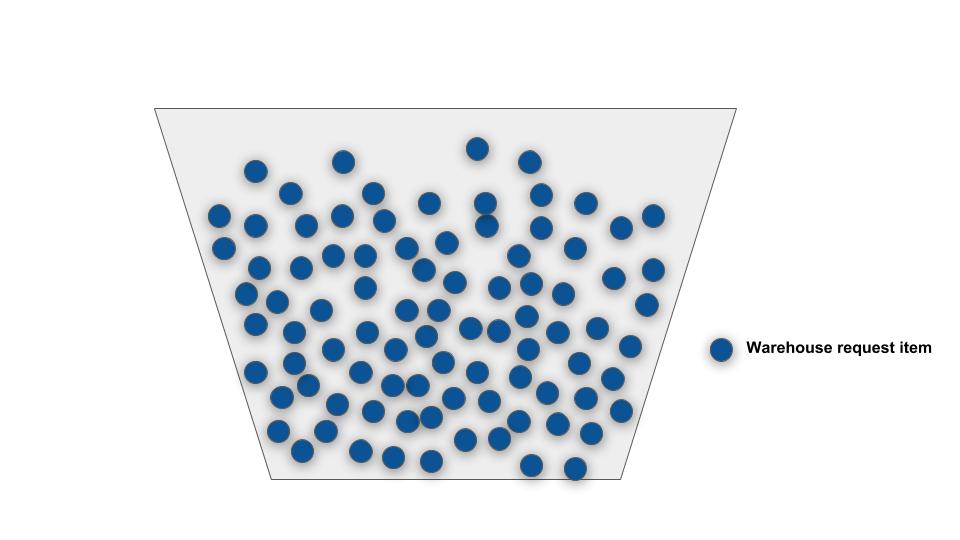

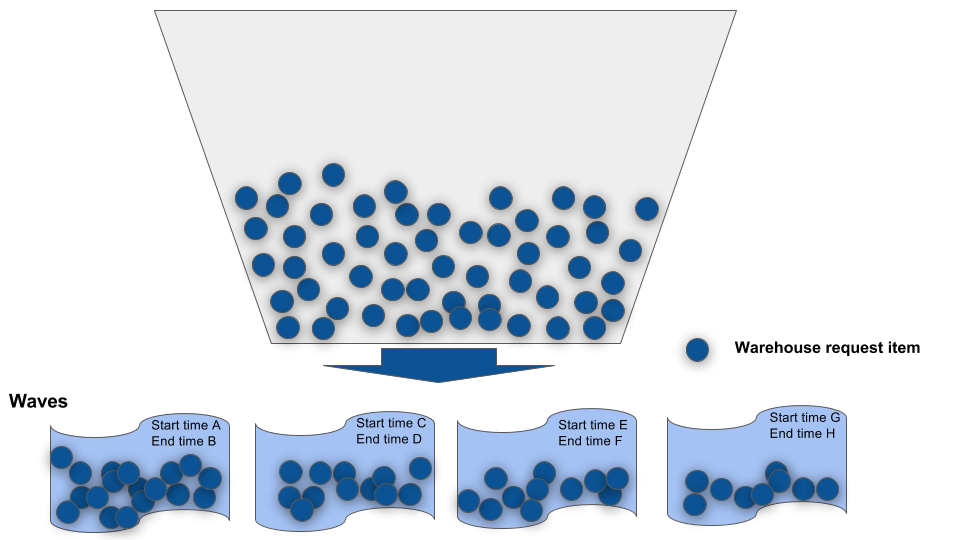

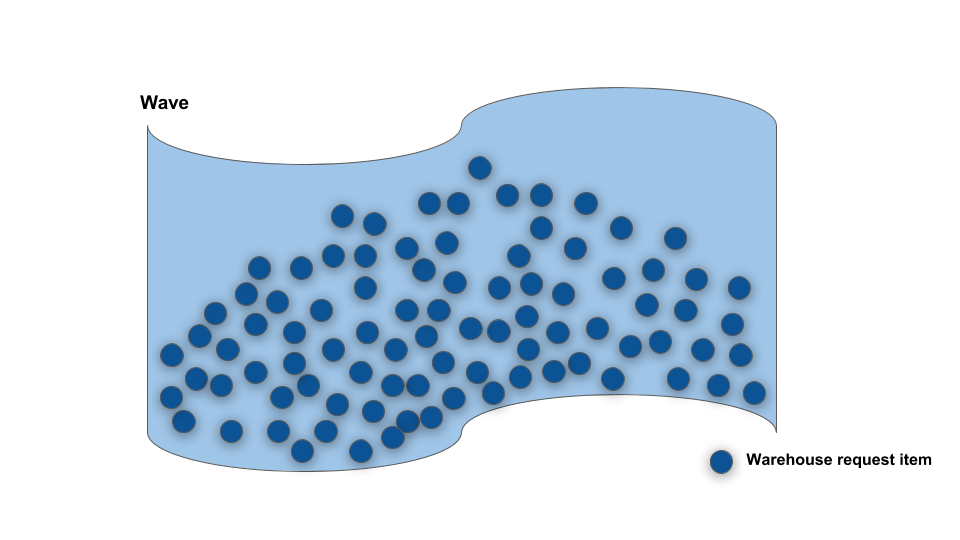

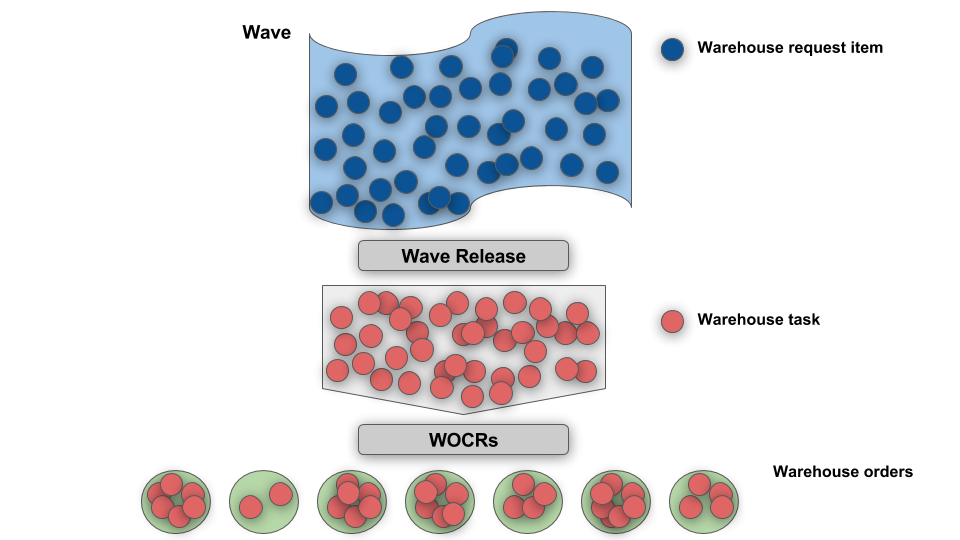

Before we start doing anything in our warehouse we receive different kind of requests to move specific objects from A to B. These requests might come from inside or outside our company and can be based on deliveries, stock transfers or posting changes. So it might be a request to move a given product from our warehouse to our end-customer or simply to move a pallet from reserve storage to the pick-face.

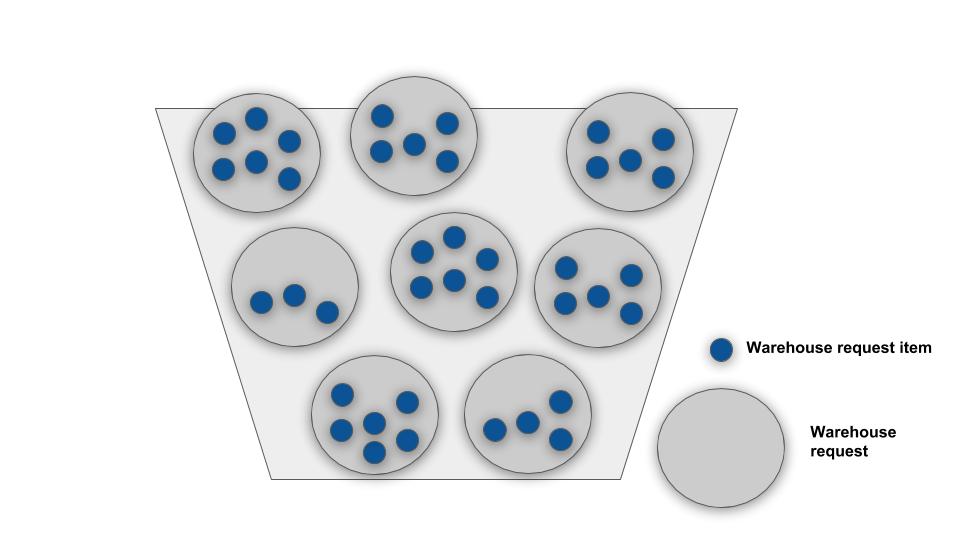

In SAP EWM we call these documents warehouse requests and for the matter of simplicity we will now concentrate on outbound deliveries as one representative group for these warehouse requests. So the delivery is our warehouse request and the items of our deliveries are our warehouse request items. First lesson learned – save the word: Warehouse request.

To make it understandable –

Imagine a big box of big balls with each big ball containing a number of small balls. The box is our request buffer, the big balls are our warehouse requests and the small balls are the warehouse request items:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

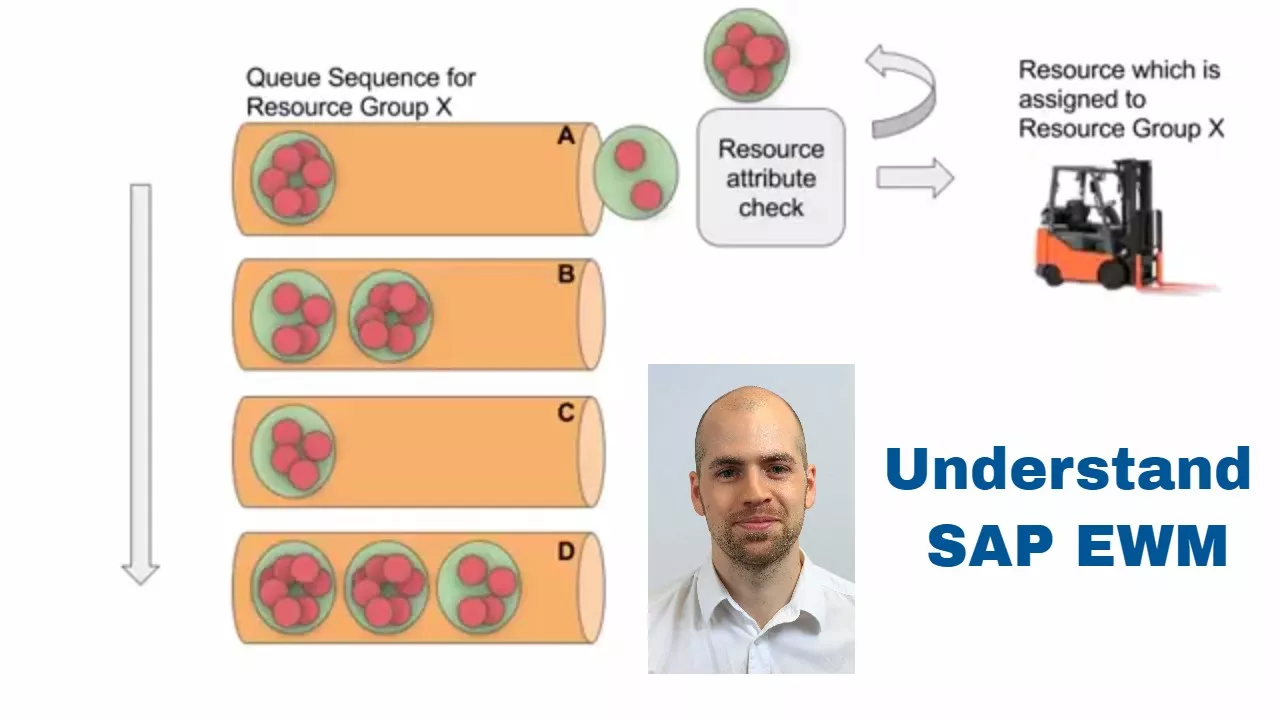

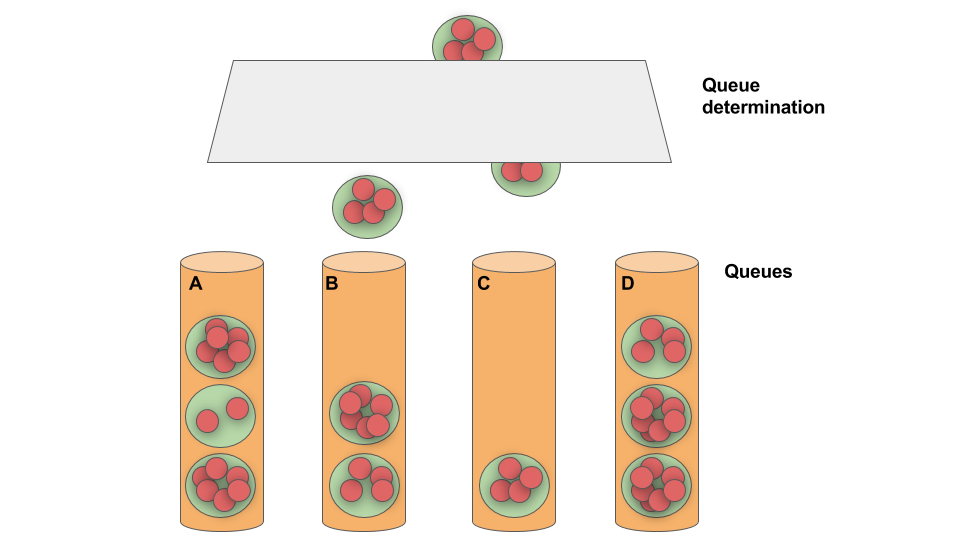

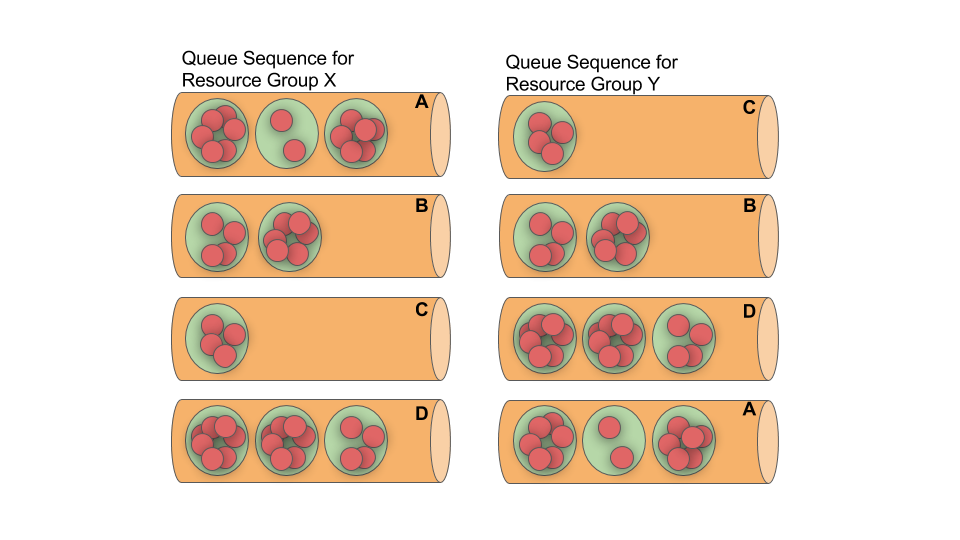

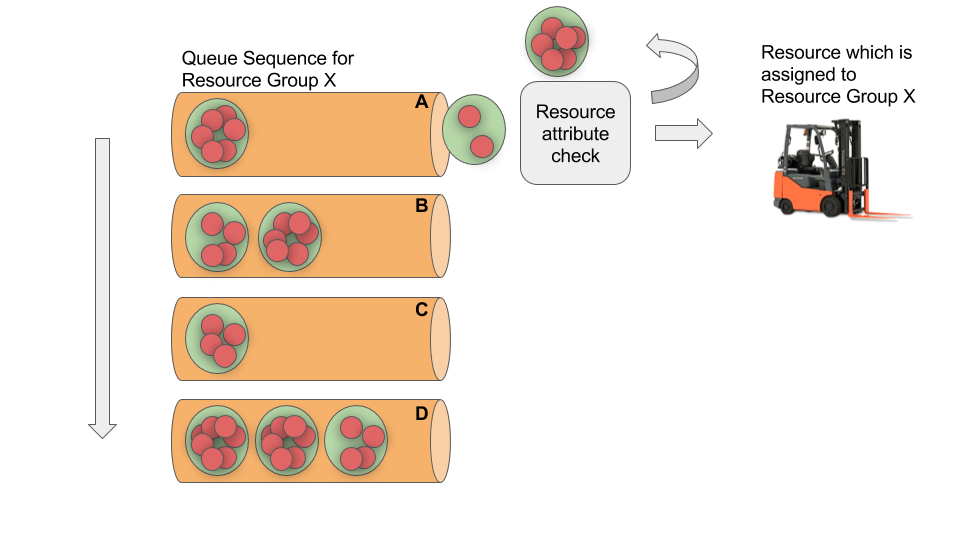

Next we bring these queues in one or more sequences and assign one sequence of queues to one group of resources. The same queues might follow sequence A for resource group X and sequence B for resource group Y:

That’s it. Not that difficult I think!

So next time we open our RF, tablet, smartphone or whatever we are using to work in our warehouse we will know now why the given request to move stuff from A to B is shown on our device and how it got there.

Note: As always, there are some exceptions and the terms mentioned above are not always used by the given definition (e.g. warehouse orders in the context of Pick & Pass process). The purpose of this article is to communicate a broad understanding of the main concept behind the given objects. Details & exceptions will be described in further posts!

I hope this blog post provides value to you and you could learn something. Please feel free to subscribe to my blog updates or my youtube channel in case you want to be notified about new posts!