Understand SAP EWM

The concept of Layout-oriented Storage Control (LOSC)

Note: This post belongs to the blog-series ‘Understand SAP EWMThe concept of Layout-oriented Storage Control’. The purpose of these series of blog-posts is to explain the concepts of the core features of SAP EWM in a simple way. We want to focus on the basic understanding rather than the smallest details.

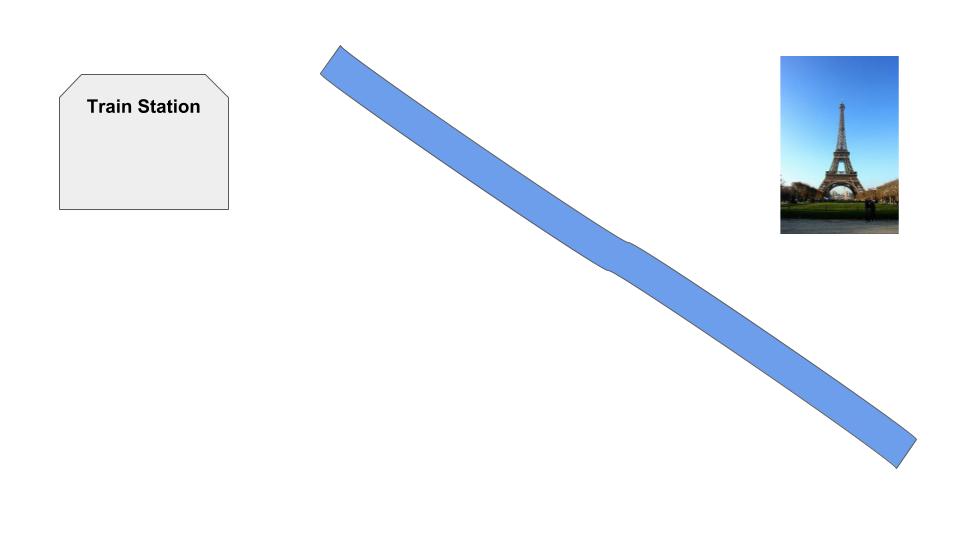

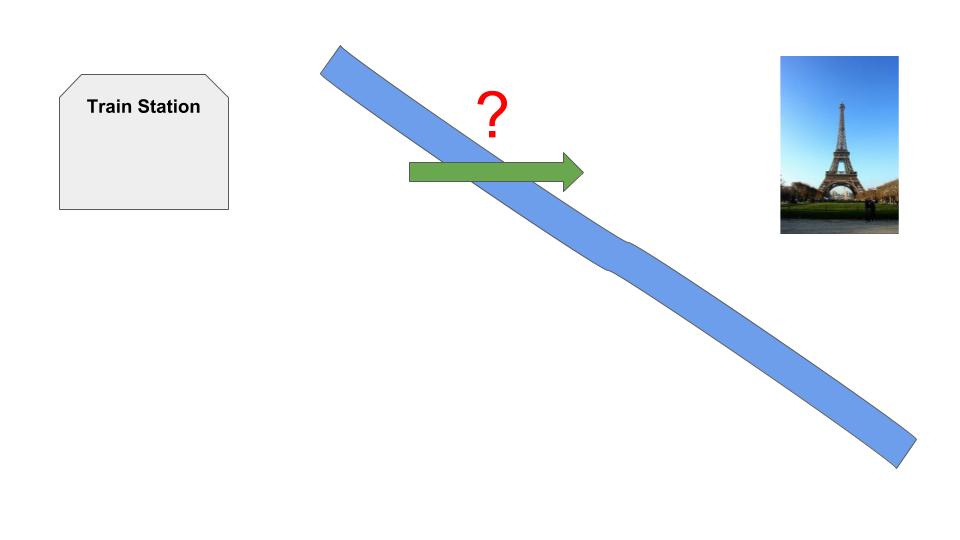

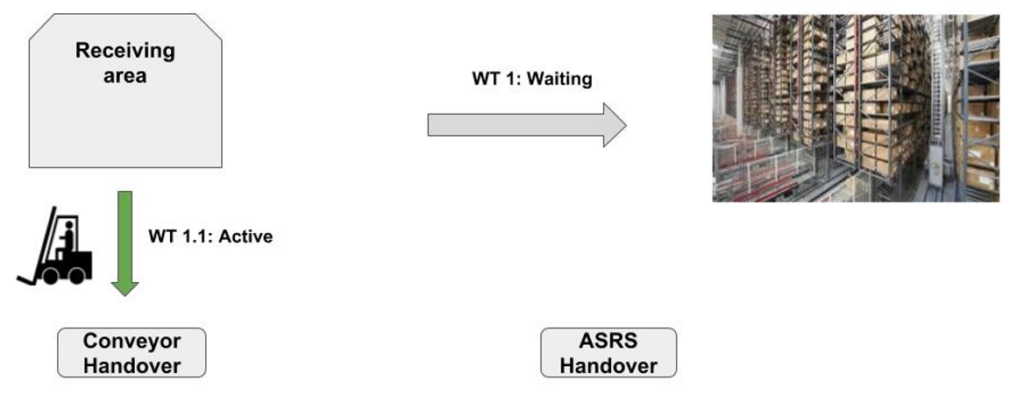

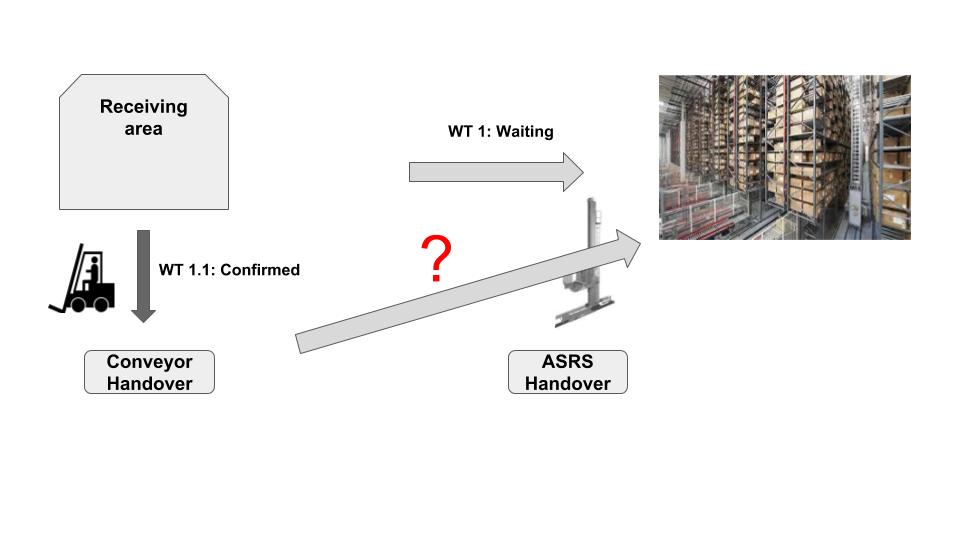

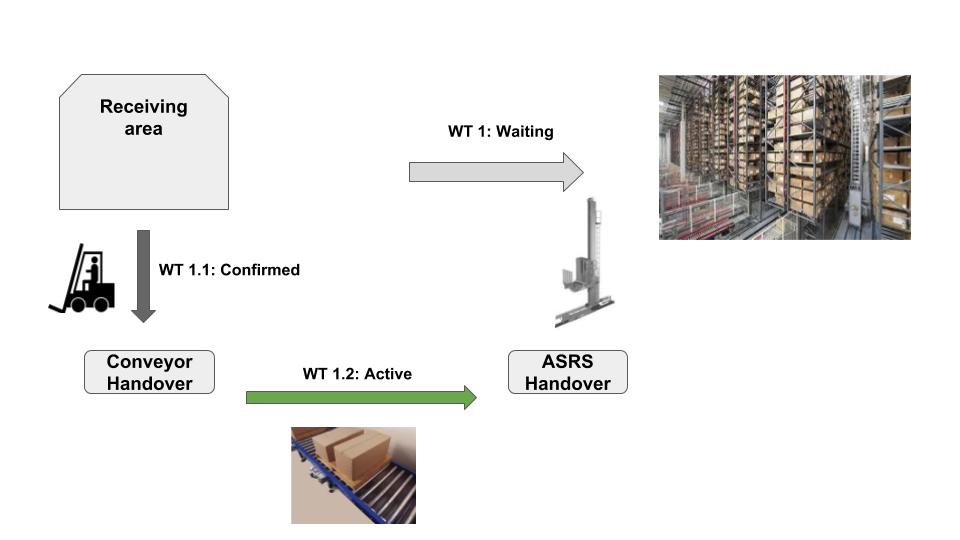

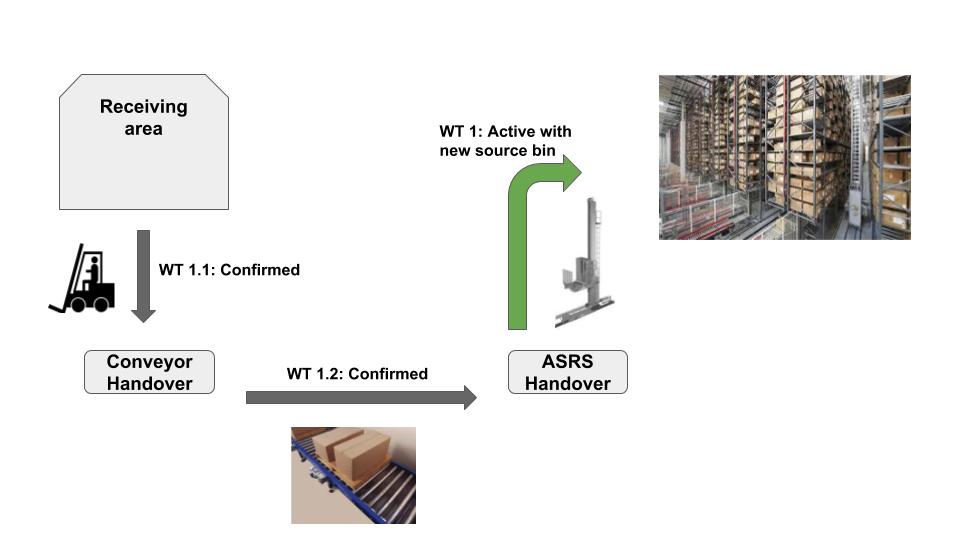

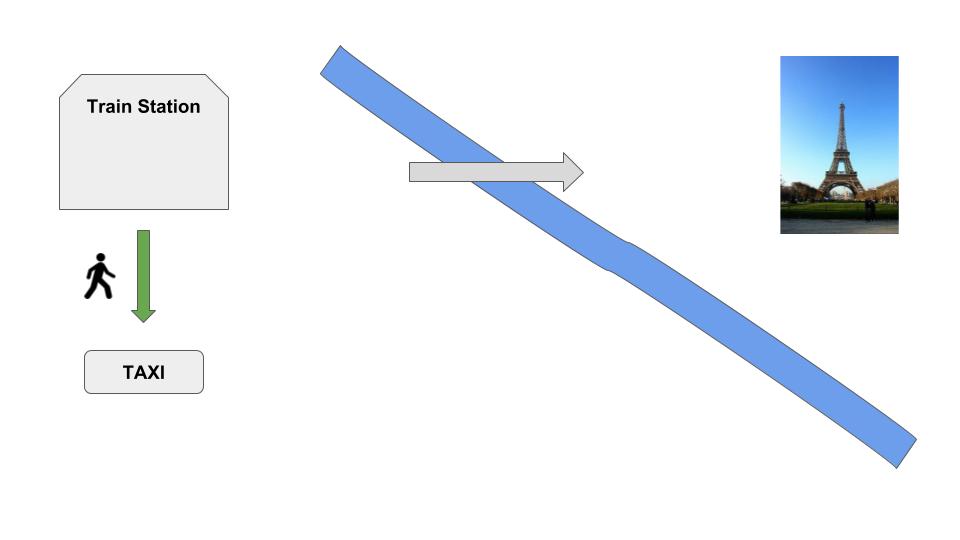

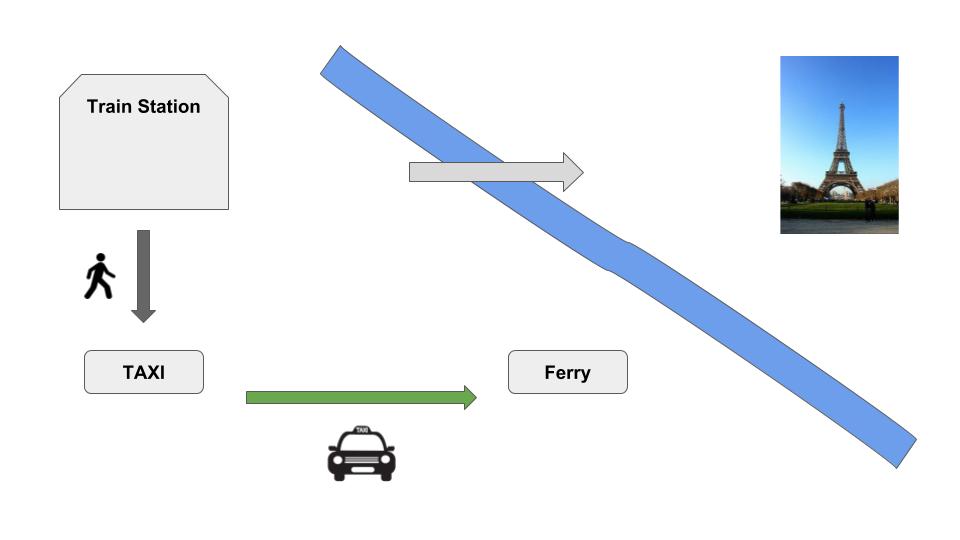

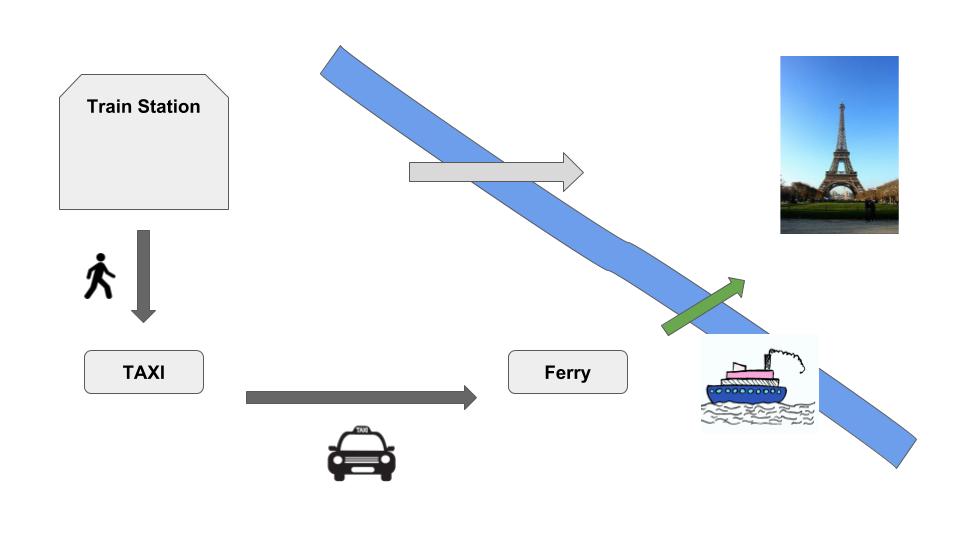

For the beginning, let us stay away from the system and try to understand how Layout-oriented storage control would look like in real life.

Imagine you go for a city trip in order to see a famous site. You arrive by train and need to find a way from the train station to the site.

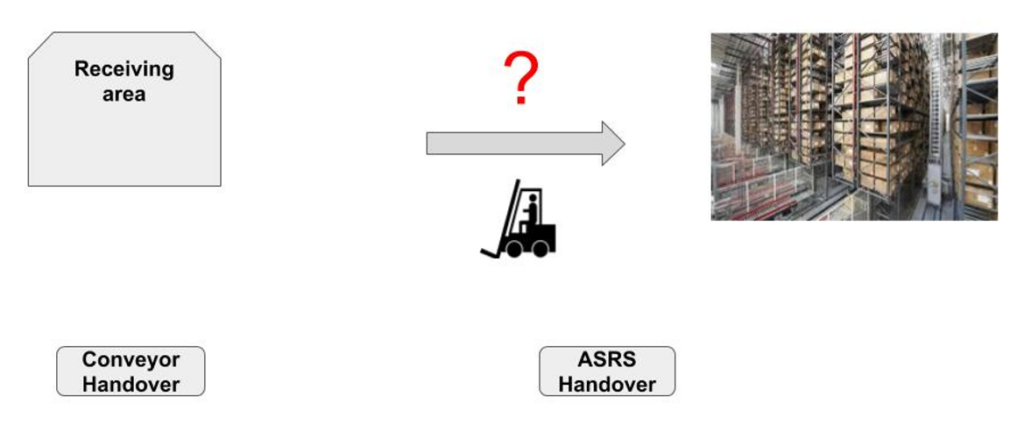

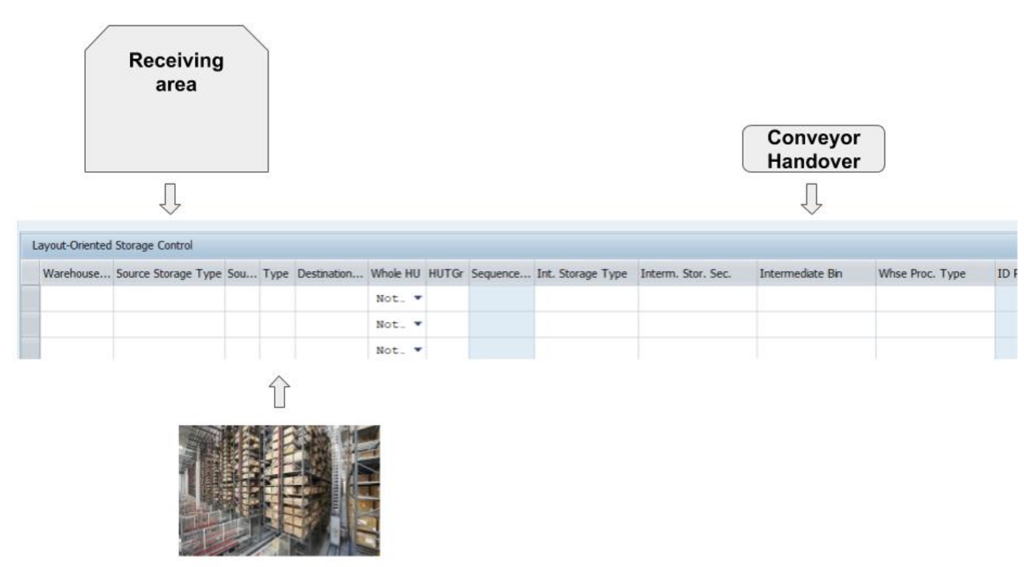

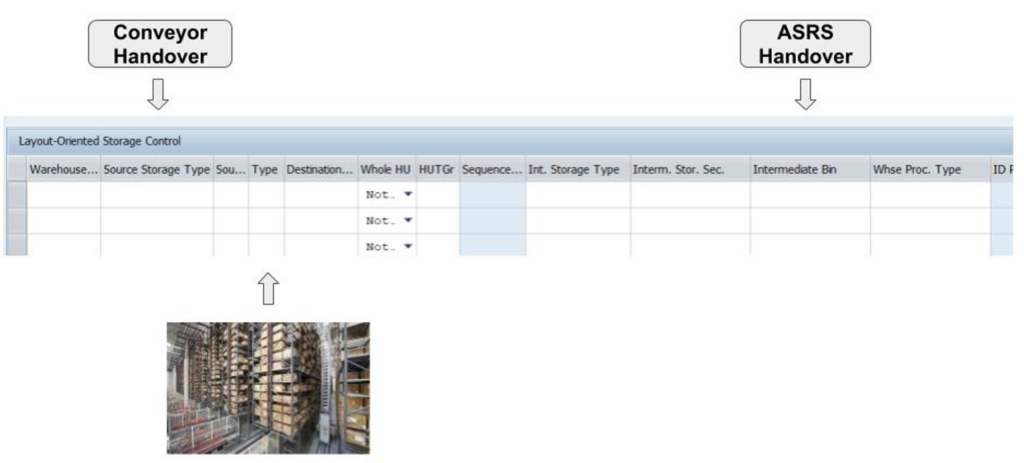

Just a quick look at a sample customizing – again a simplified view as we are not interested in all details and possible configuration options at this point.

For our example flow we would need at least two records.

The first record would have the receiving area as the source storage type and the pallet rack as the destination. The intermediate bin for this records would be the conveyor handover.

I hope this blog post provides value to you and you could learn something. Please feel free to subscribe to my blog updates or my youtube channel in case you want to be notified about new posts!