Reveal SAP EWM

Storage bin sorting during putaway (CLSP)

This blog is supposed to clear up one of the biggest misconceptions in the context of bin determination during putaway task creation in SAP EWM.

Before we jump into the system, let us quickly make sure to understand the scenario from material flow / process perspective –

Imagine you want to putaway a handling unit – let us assume a pallet loaded with some cartons – into a pallet rack. You have defined a strategy to determine an empty bin. All bins have the same bin type. So far so good. However, there might be lots of empty bins in the given rack. So how should EWM now decide which bin to suggest for the putaway process?

At this point, the bin sorting comes into the game!

I will explain the topic for you based on the following agenda:

- The standard logic

- The configuration

- The bin sorting

- The coding

- Options for enhancement

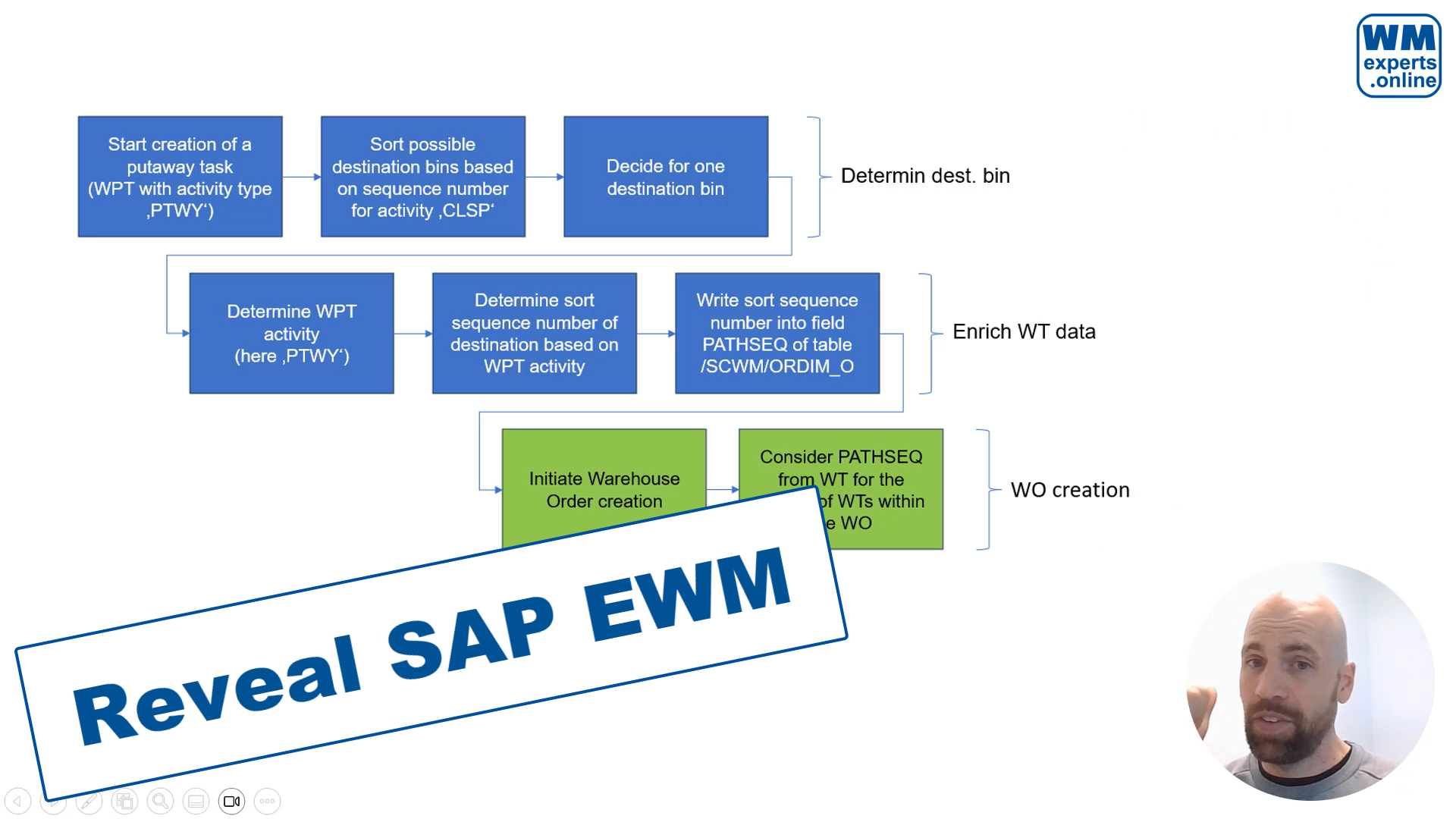

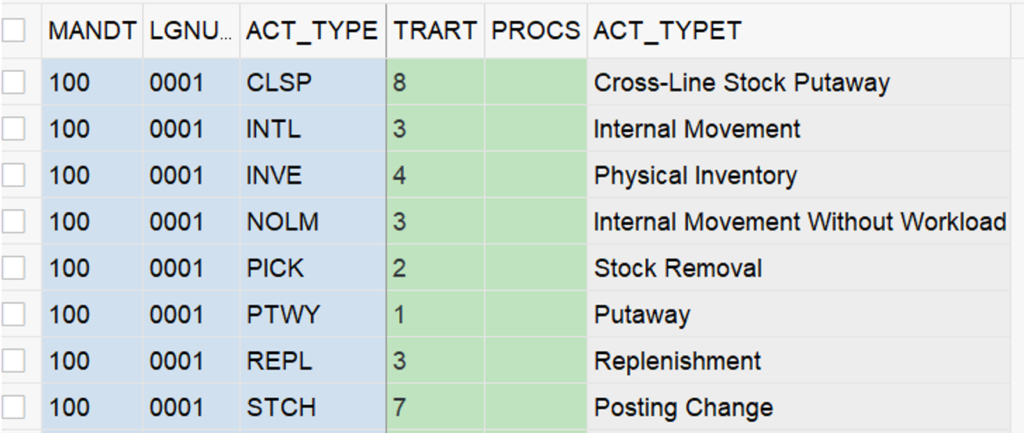

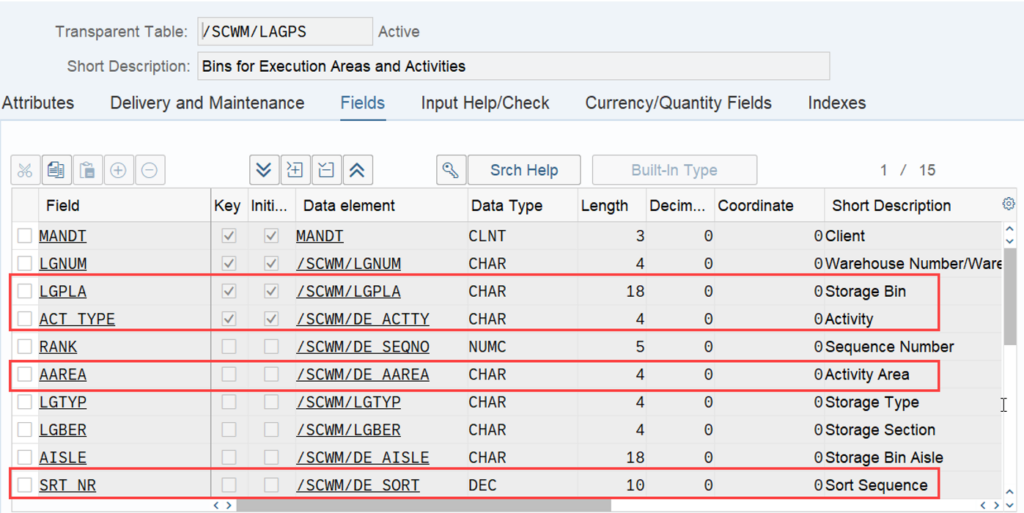

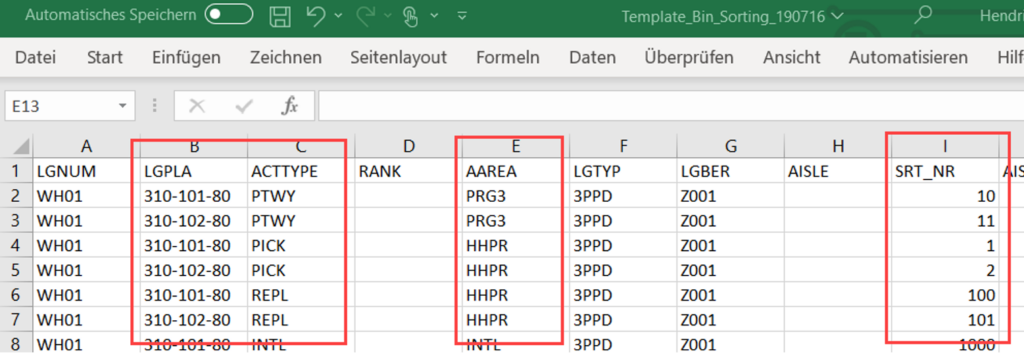

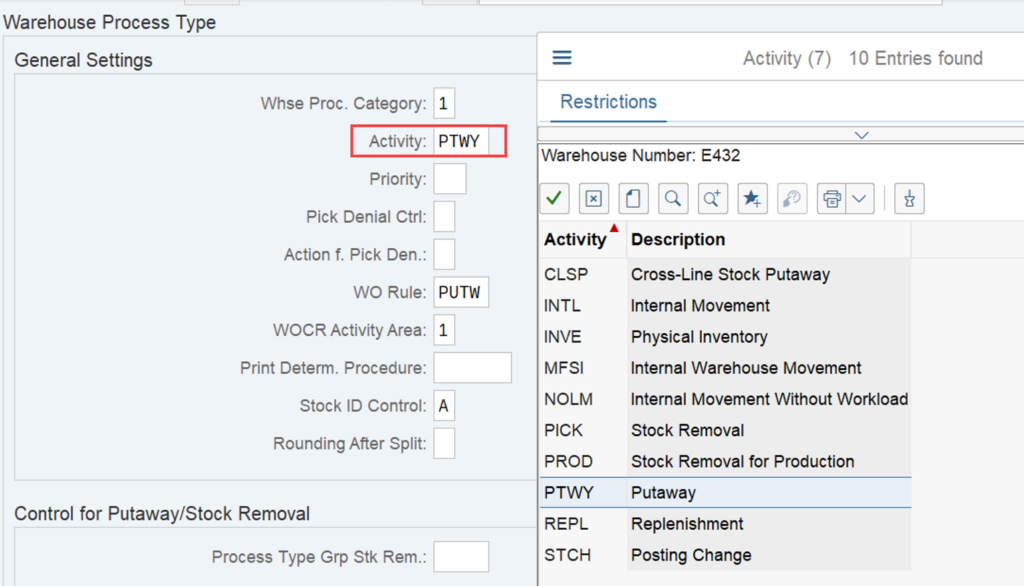

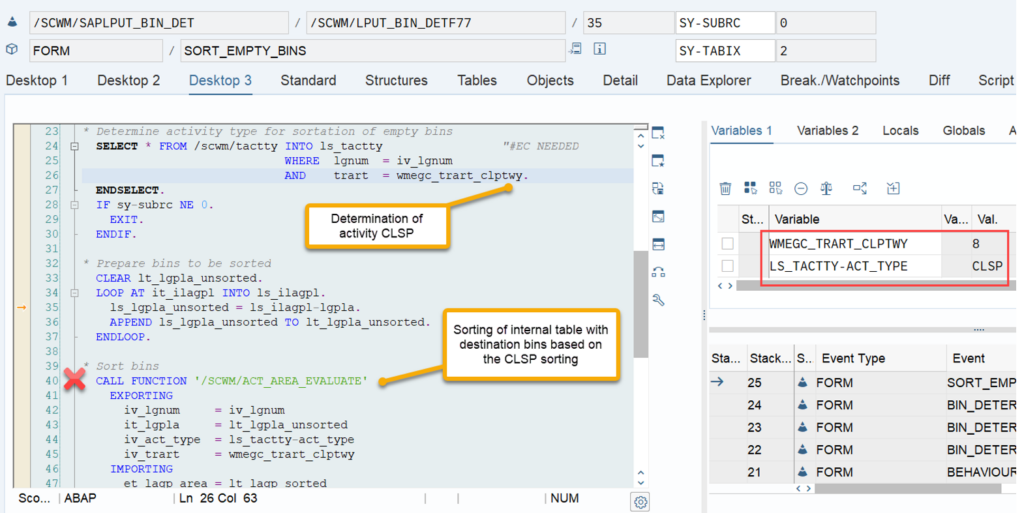

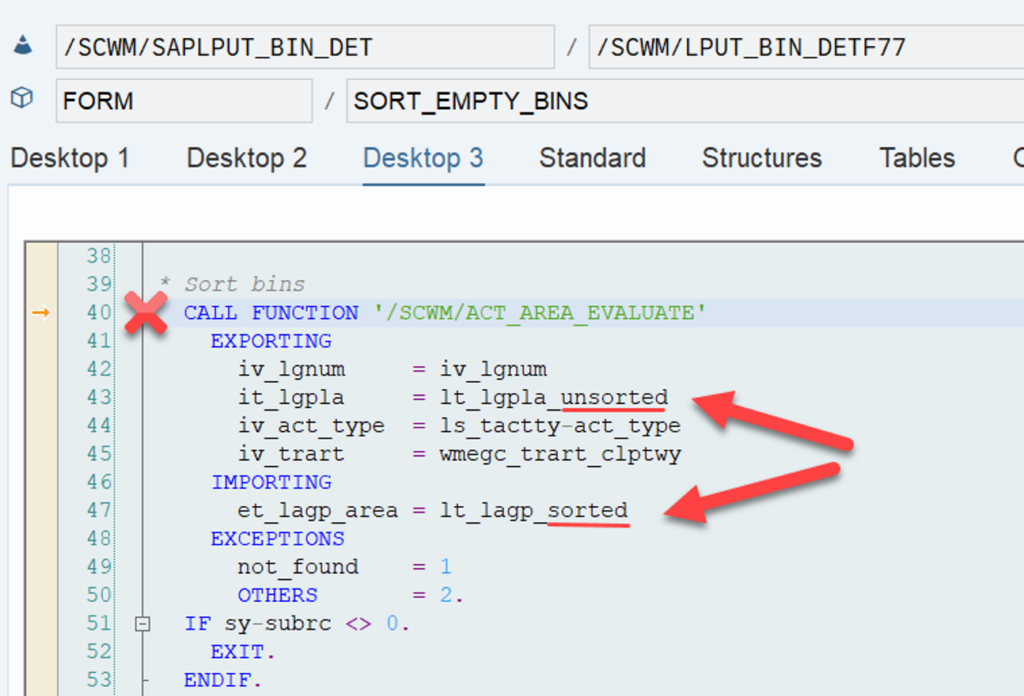

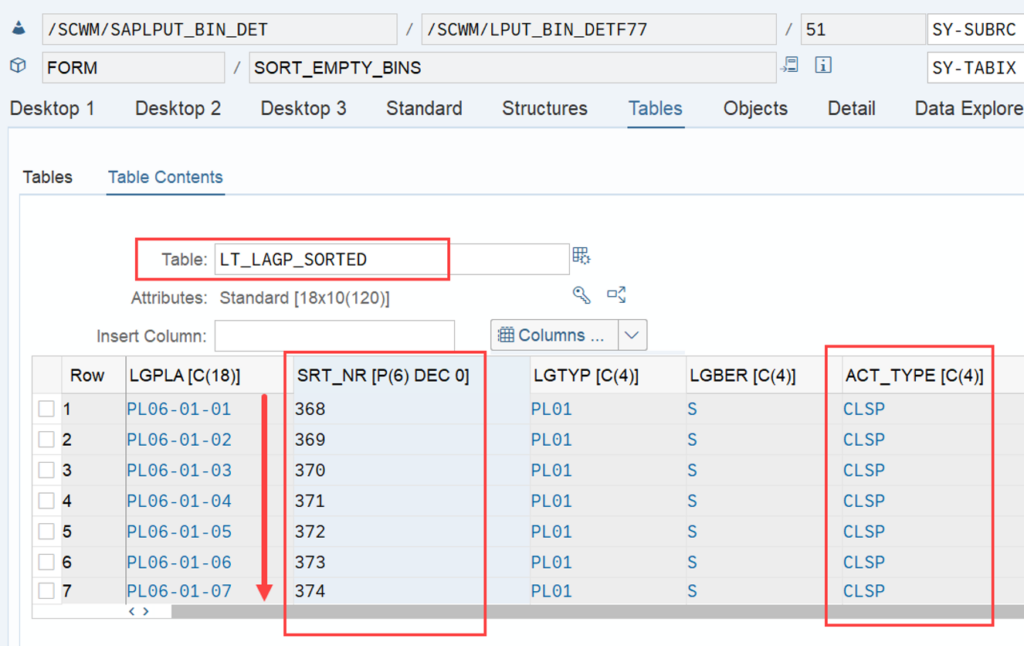

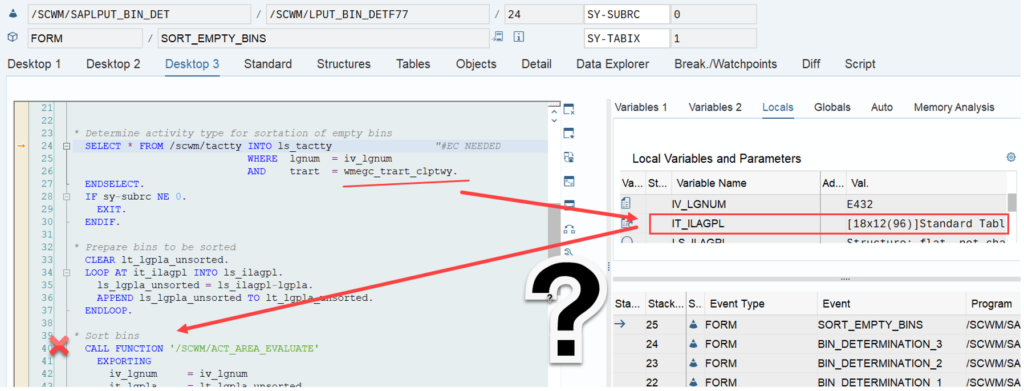

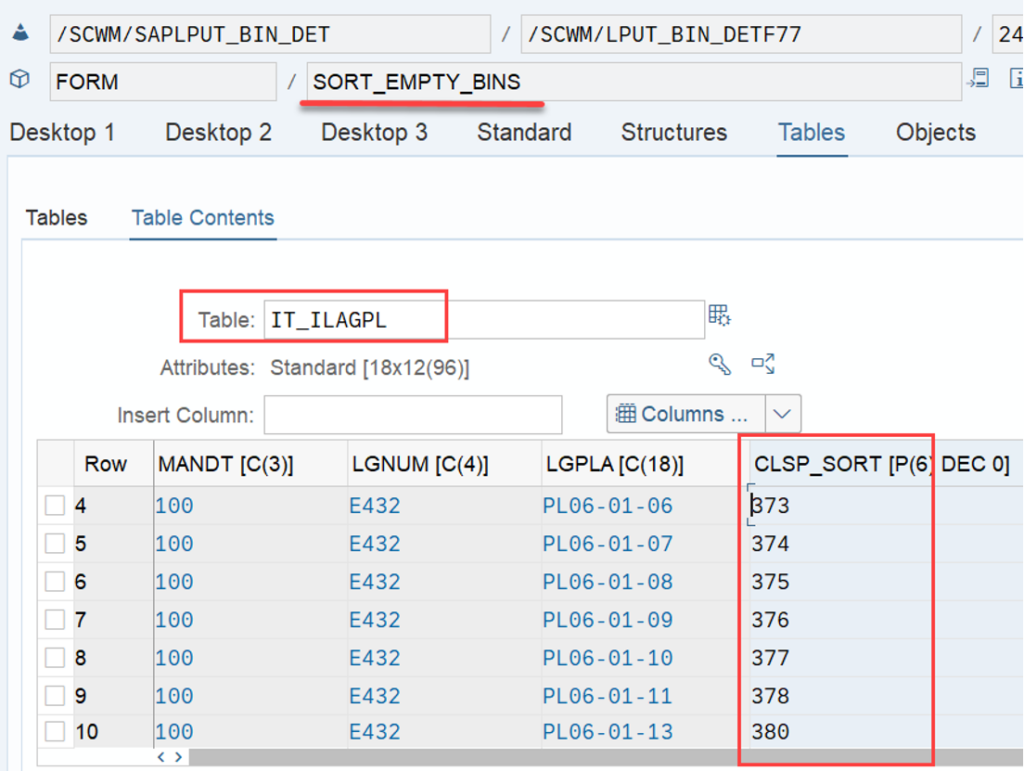

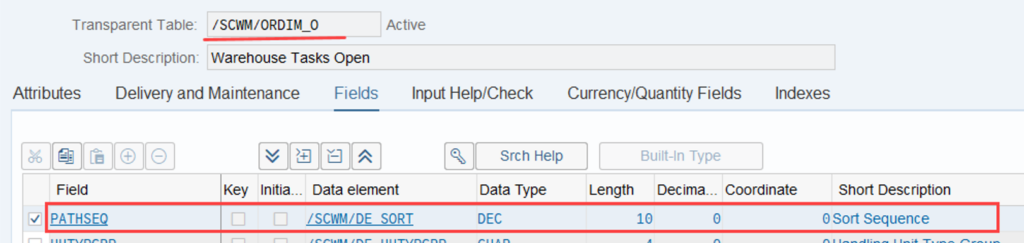

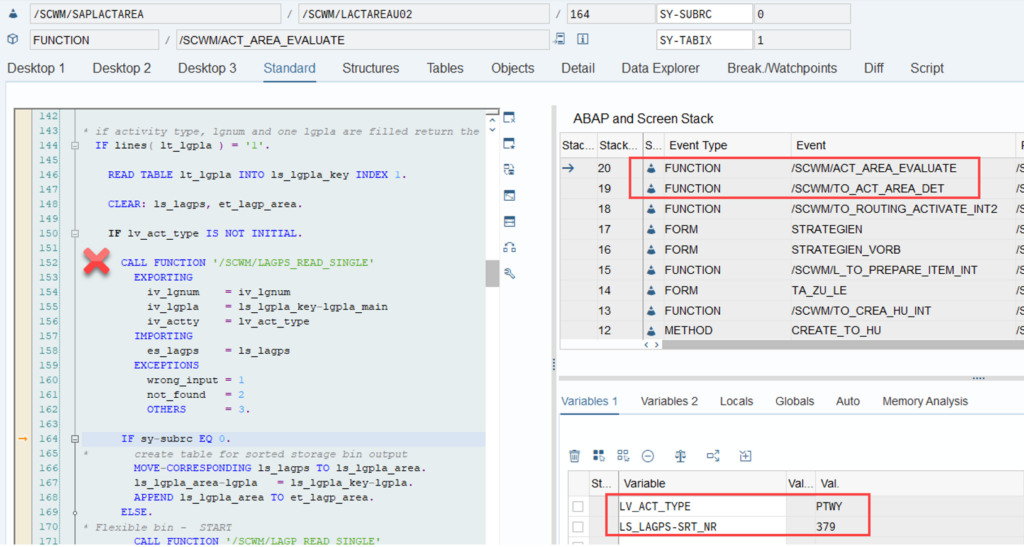

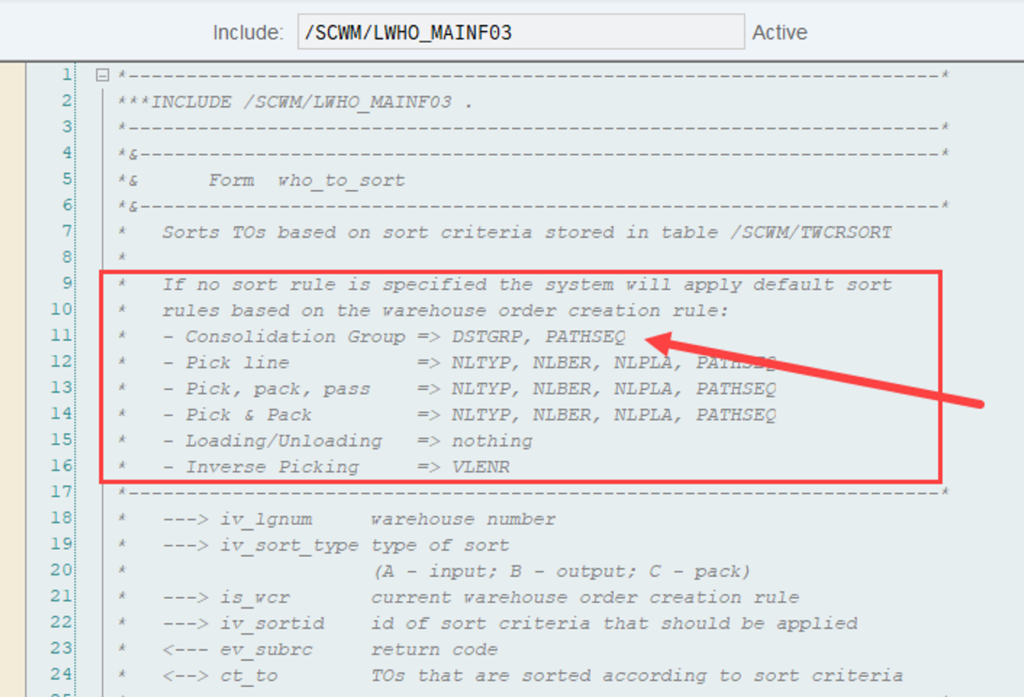

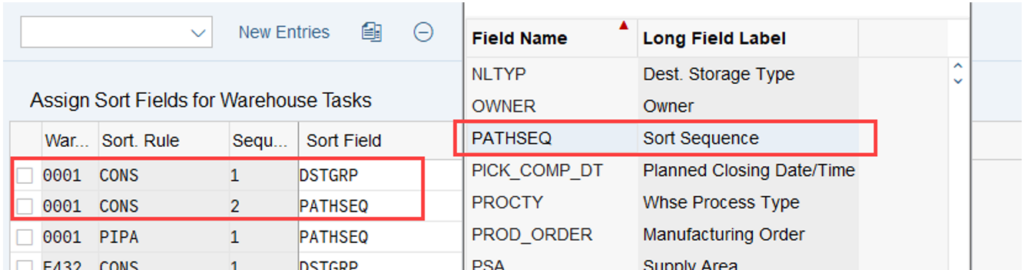

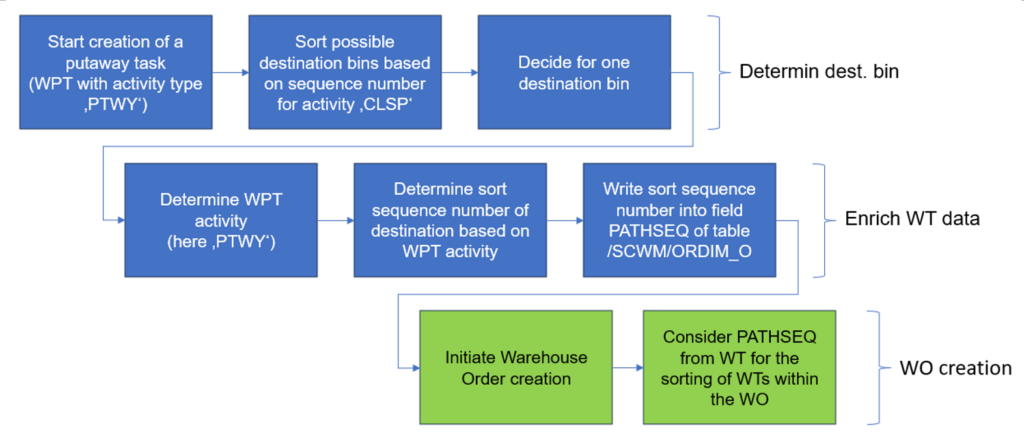

As a starting point it is important to understand that whenever EWM is sorting something based on storage bins (e.g. warehouse tasks within warehouse orders, bins during putaway etc.) it is using so called ‘sort sequence numbers’. Those numbers are assigned to storage bins. EWM never uses those sequence numbers alone. It usually uses a combination of a sequence number along with an activity area and an activity type. Different combinations of activities, activity areas and sequence numbers can be attached to storage bins. Either based on the execution of a report (which is reading the sorting logic from the customizing) or based on an excel upload file.

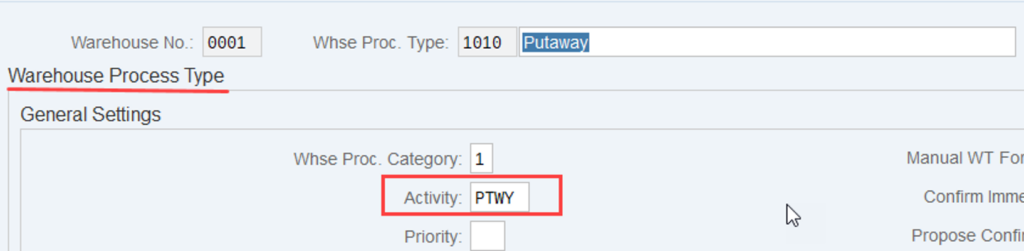

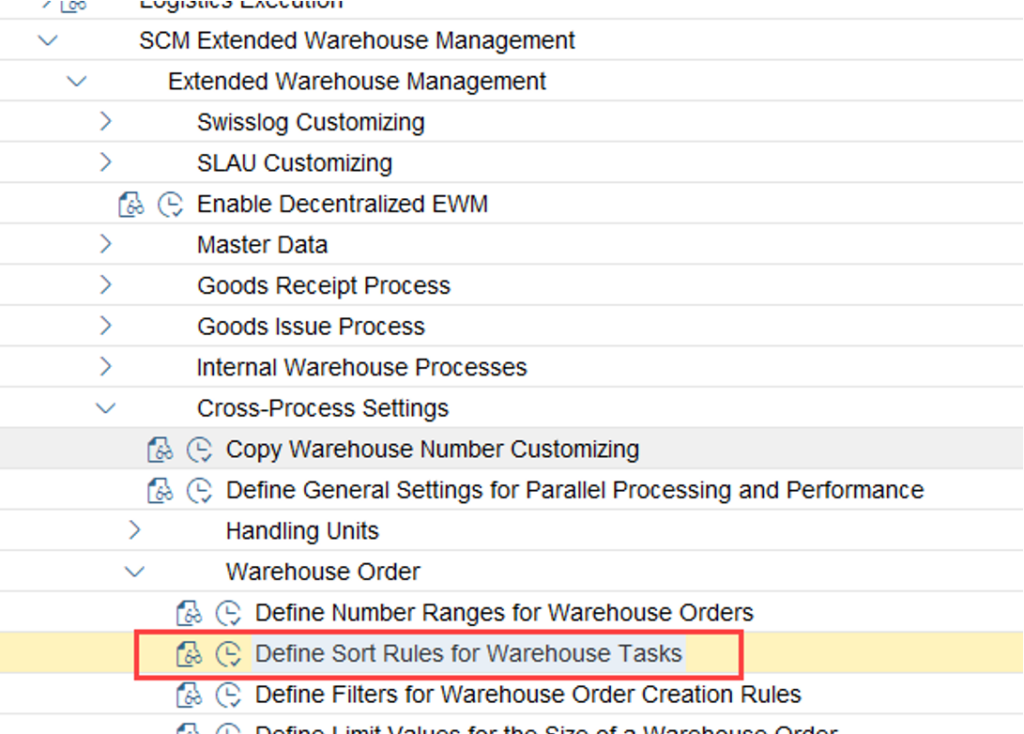

The configuration

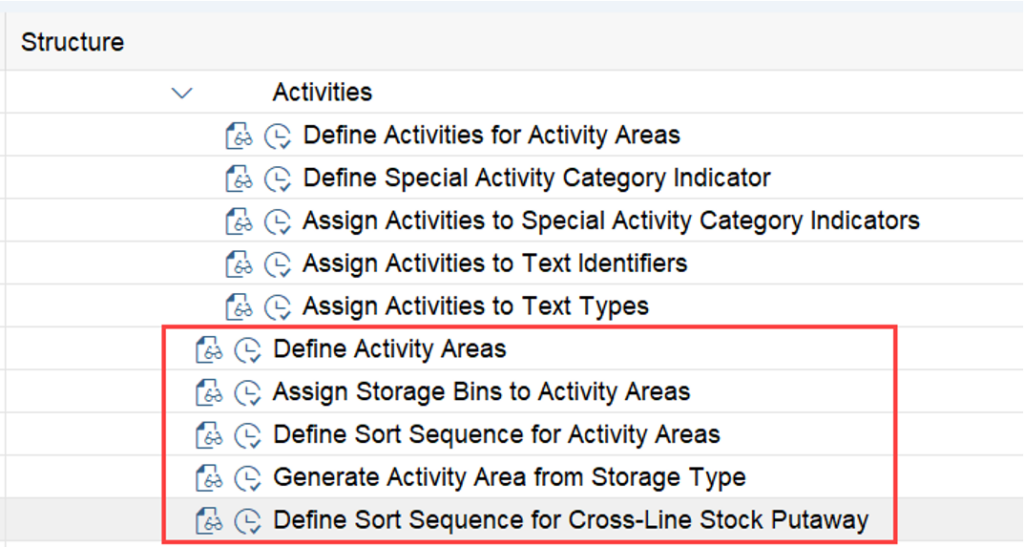

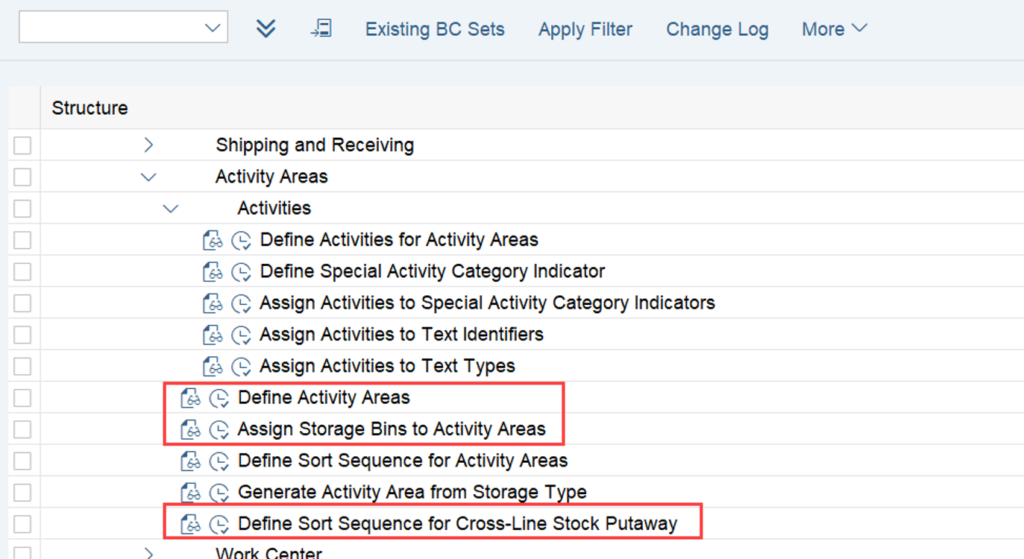

The creation of the activity area and its sorting can be done here:

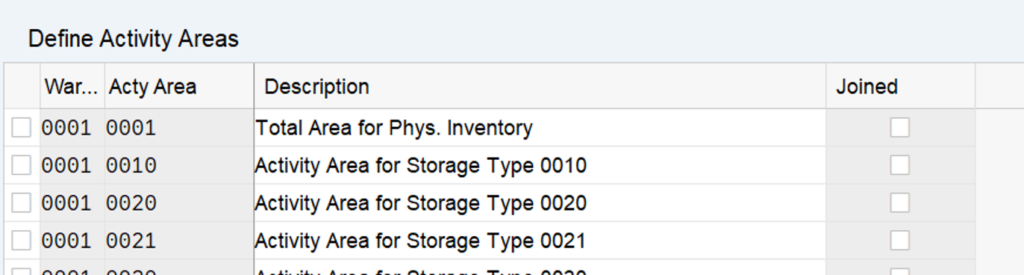

- Define an activity area via SPRO: SCWM Extended Warehouse Management -> Extended Warehouse Management -> Master Data -> Activities Areas -> Define Activity Areas

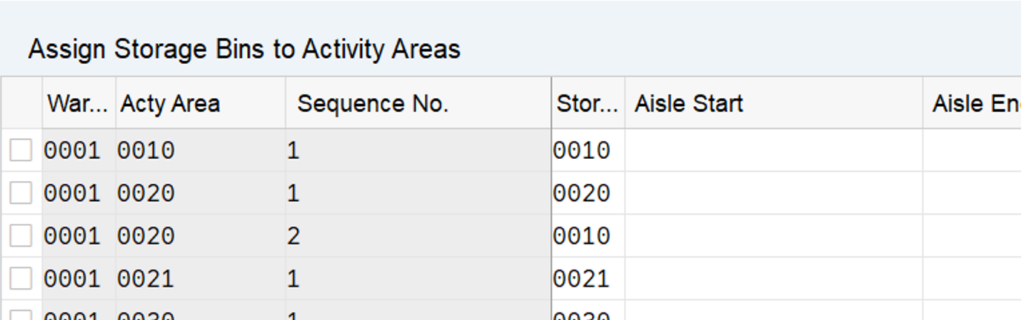

- Then assign this Activity Area to storage type. Path in SPRO: SCWM Extended Warehouse Management -> Extended Warehouse Management -> Master Data -> Activities Areas -> Assign Storage Bins to Activity Areas

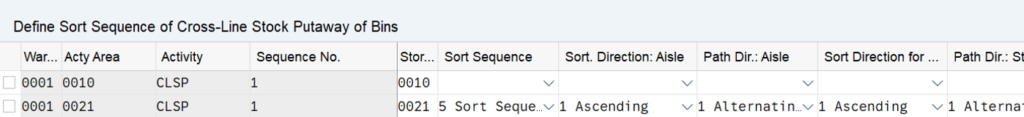

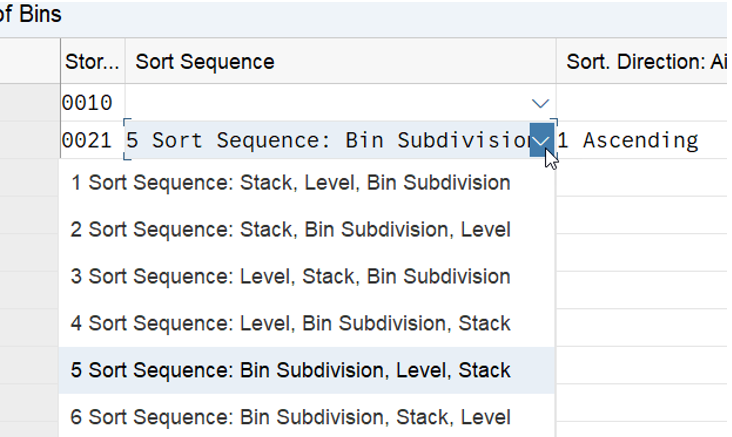

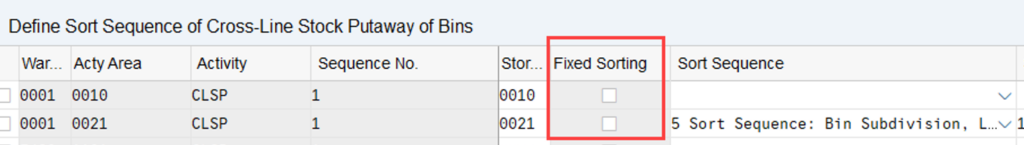

- Then define sort sequence for CLSP Activity. Path in SPRO: SCWM Extended Warehouse Management -> Extended Warehouse Management -> Master Data -> Activities Areas -> Define Sort Sequence for Cross-Line Stock Putaway

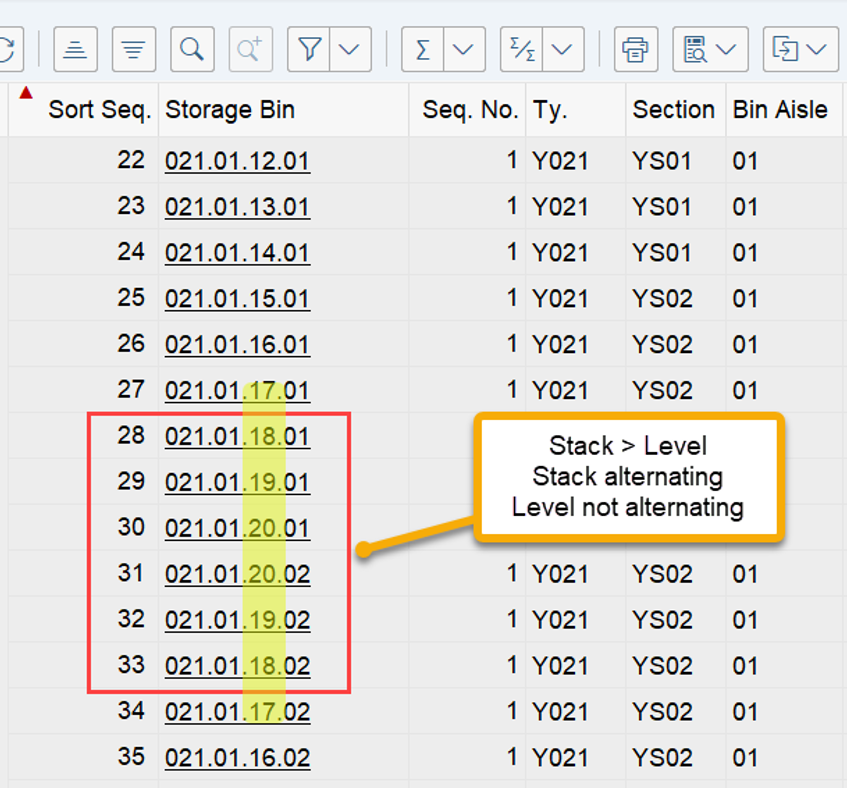

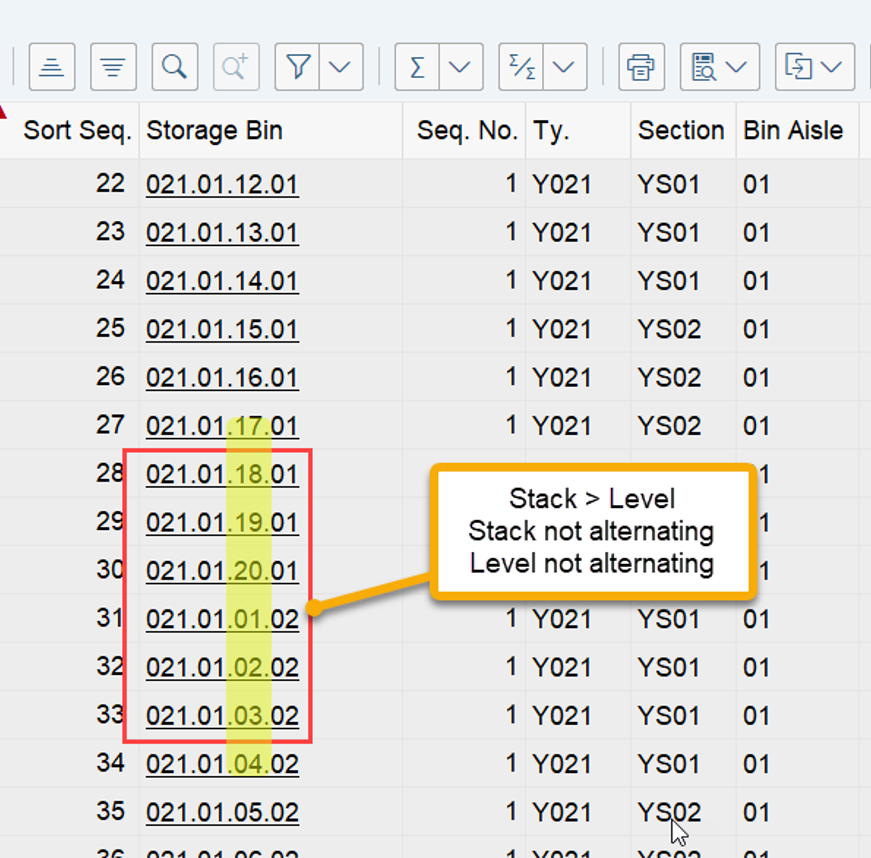

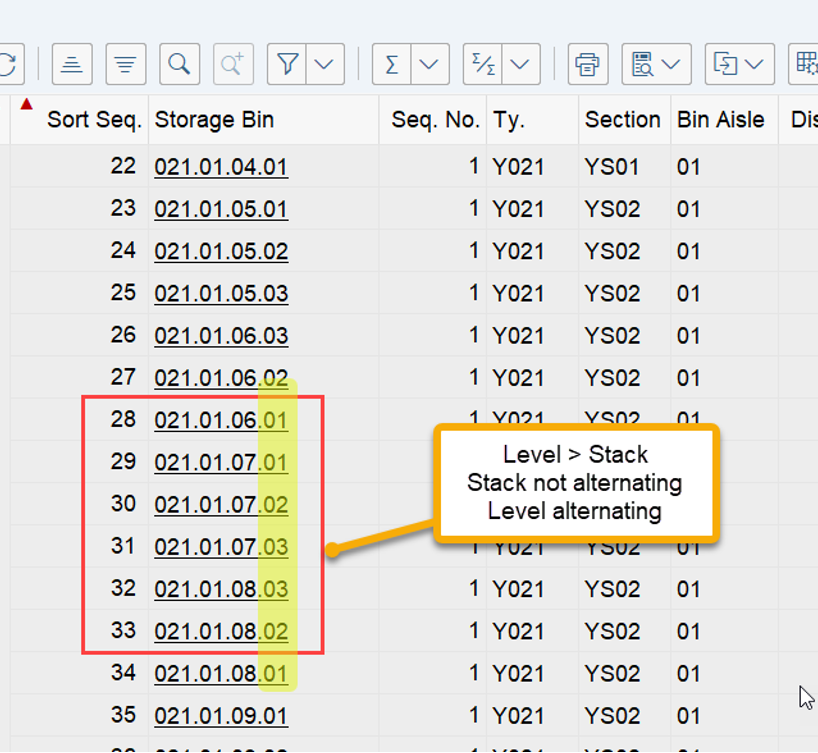

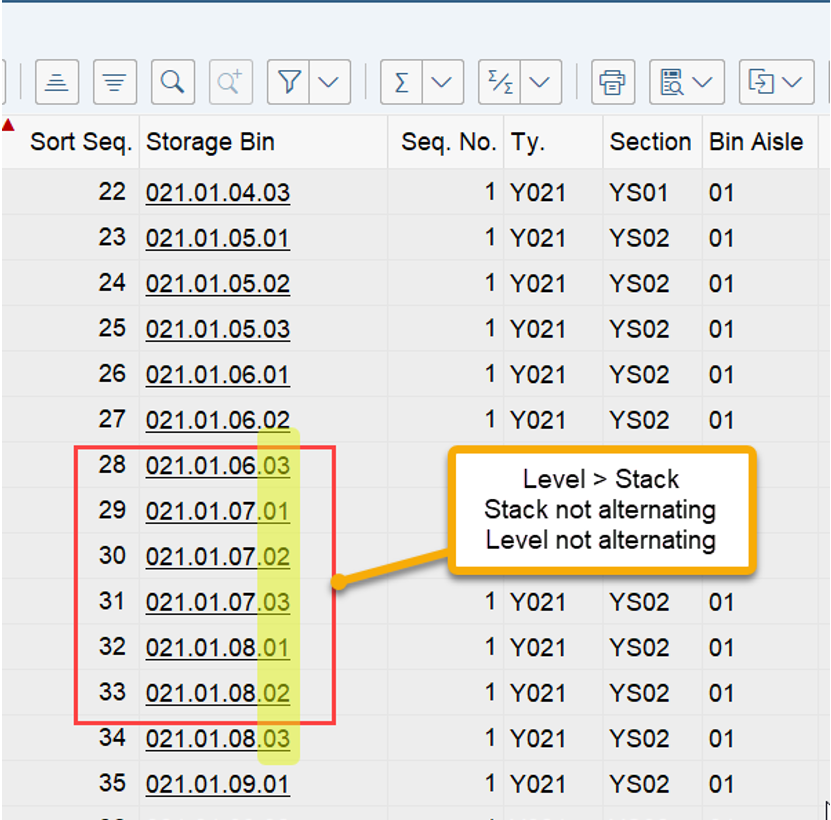

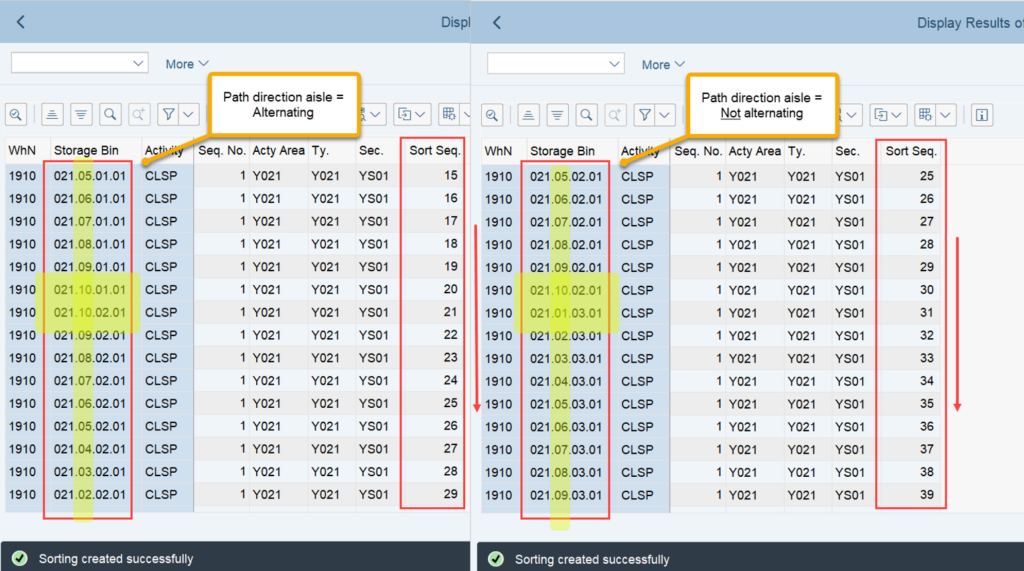

The bin sorting

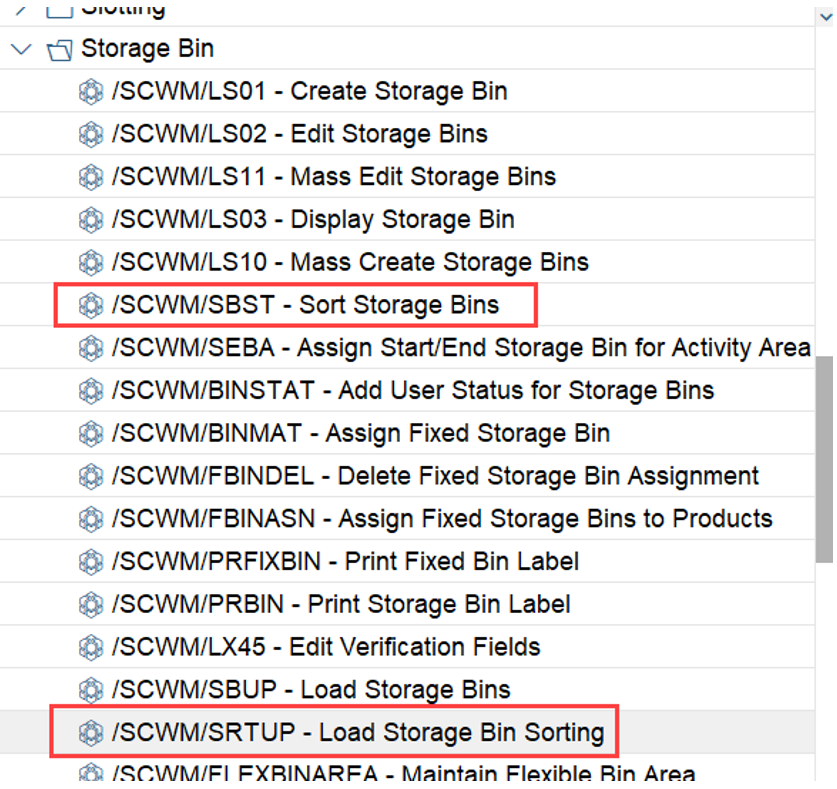

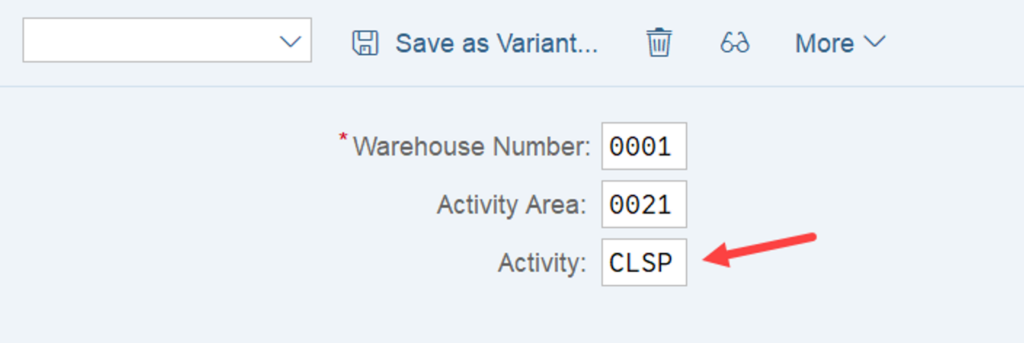

Once the customizing is completed as shown above, the bins have to be sorted via transaction /SCWM/SBST:

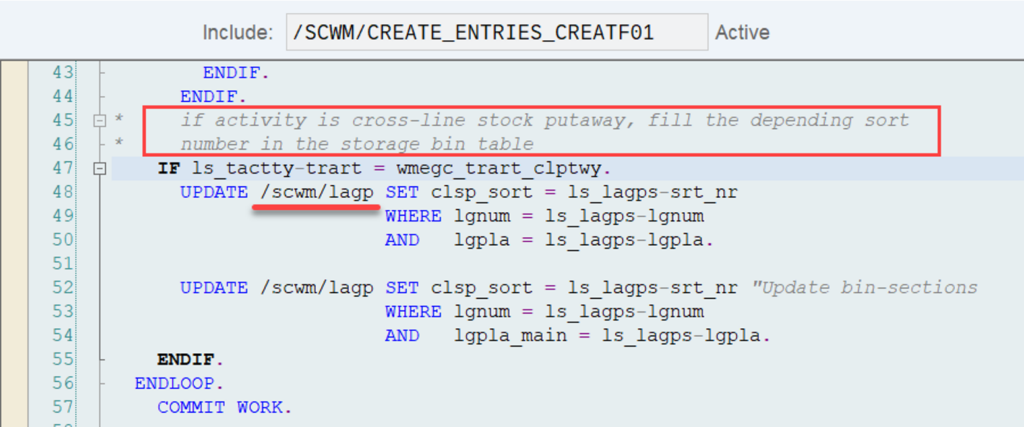

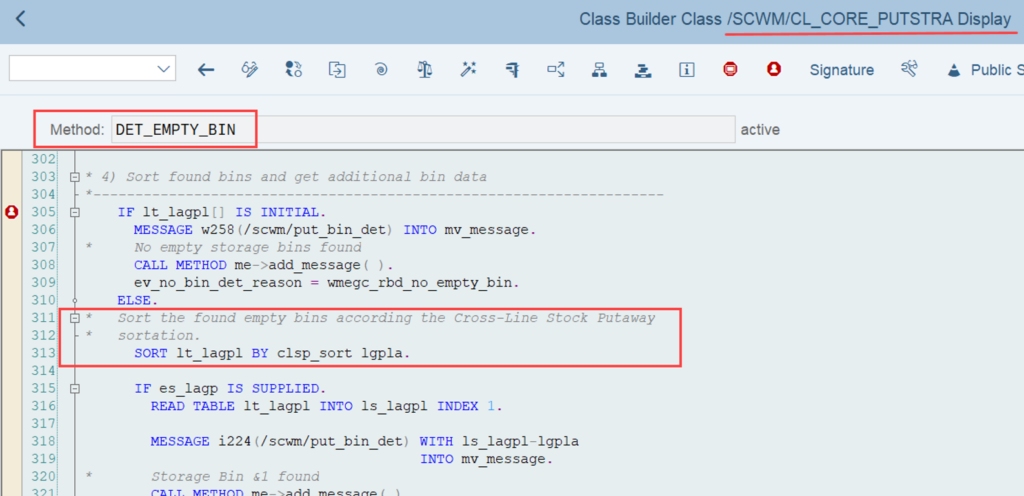

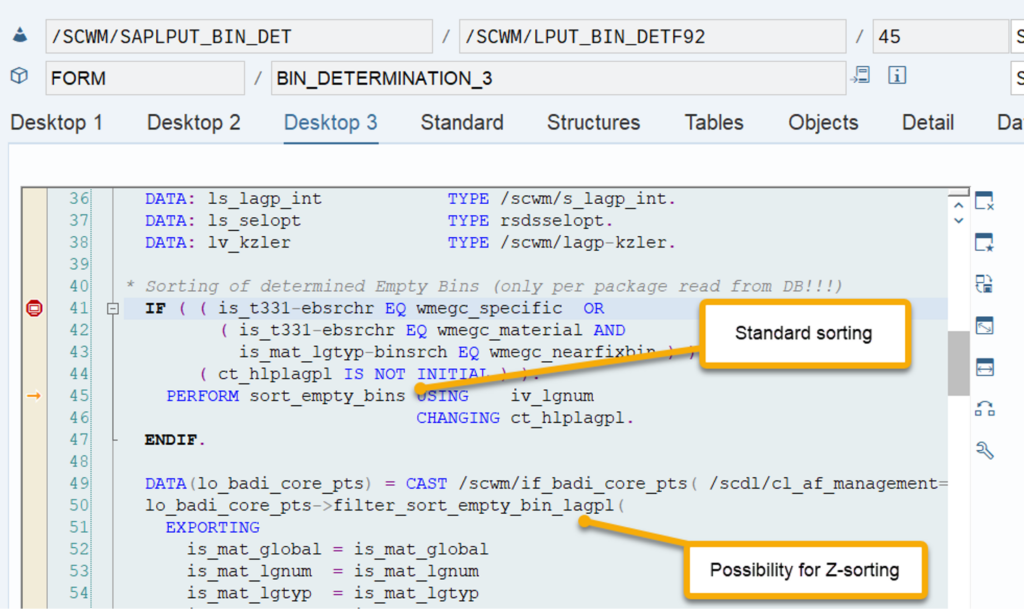

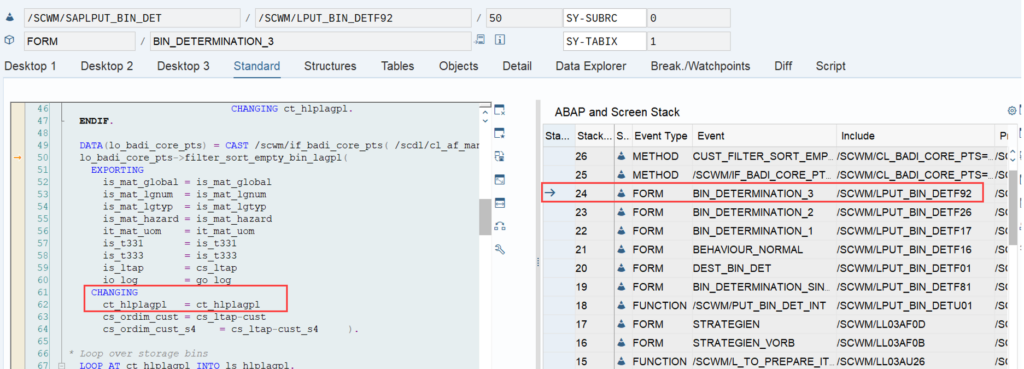

The coding

Options for enhancements

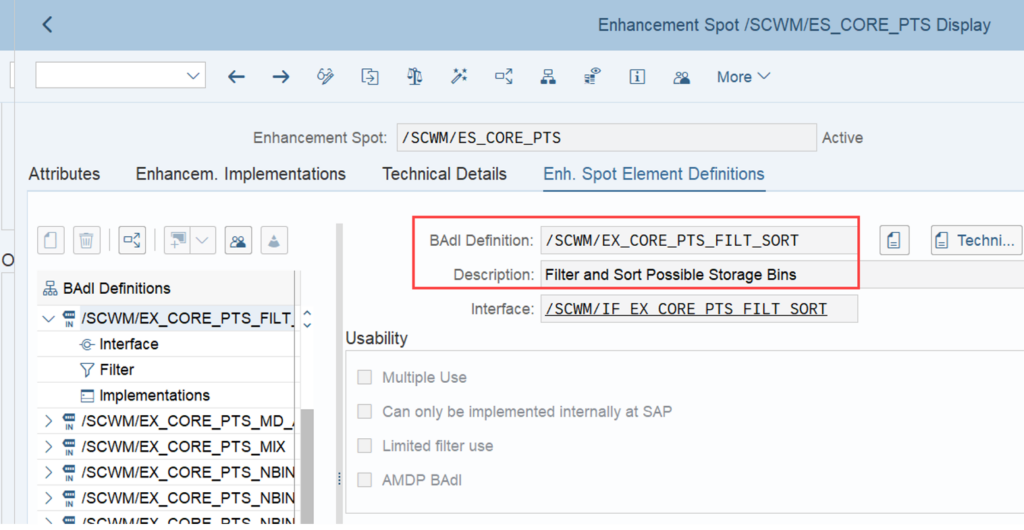

As you know it from my previous blog posts, I use to give you some options to enhance the standard logic. This section is limited to the sorting of bins during the determination of the destination. Enhancements of the sorting within the WOs is not in scope here. You can look into this blog post in case you want to learn more about enhancing the WOCRs.

Badi /SCWM/EX_CORE_PTS_FILT_SORT is one that will work here for sure, as the name already suggests:

EWM delivers a sample implementation which might give you some good ideas about how to implement a custom sorting here (class /SCWM/CL_EI_CORE_PTS_FILT_SORT).

Final thoughts & remarks

- The sort sequence number for CLSP is only relevant in case multiple bins are available with the same characteristics related to your putaway strategy. EWM first determines optimal bins e.g. based on the bin type and/or the storage section. Only if multiple valid bins exist with the optimal combination, the sequence numbers for CLSP sorting are applied

- You might have noticed that if you do not create the activity area and the sorting for the CLSP activity at all, you will still get a destination bin during putaway task creation. In this case, EWM will simply sort the bins by their names.

- Seems SAP also noticed that the topic is quite confusing. They released note 2992048 but you do not need to read that once you’ve read and understand this blog post 🙂

…and here we are again at the end of the article. The intention of this blog post was to shed some light and help you to avoid confusion around this topic. Hope I could provide some value for one or the other!