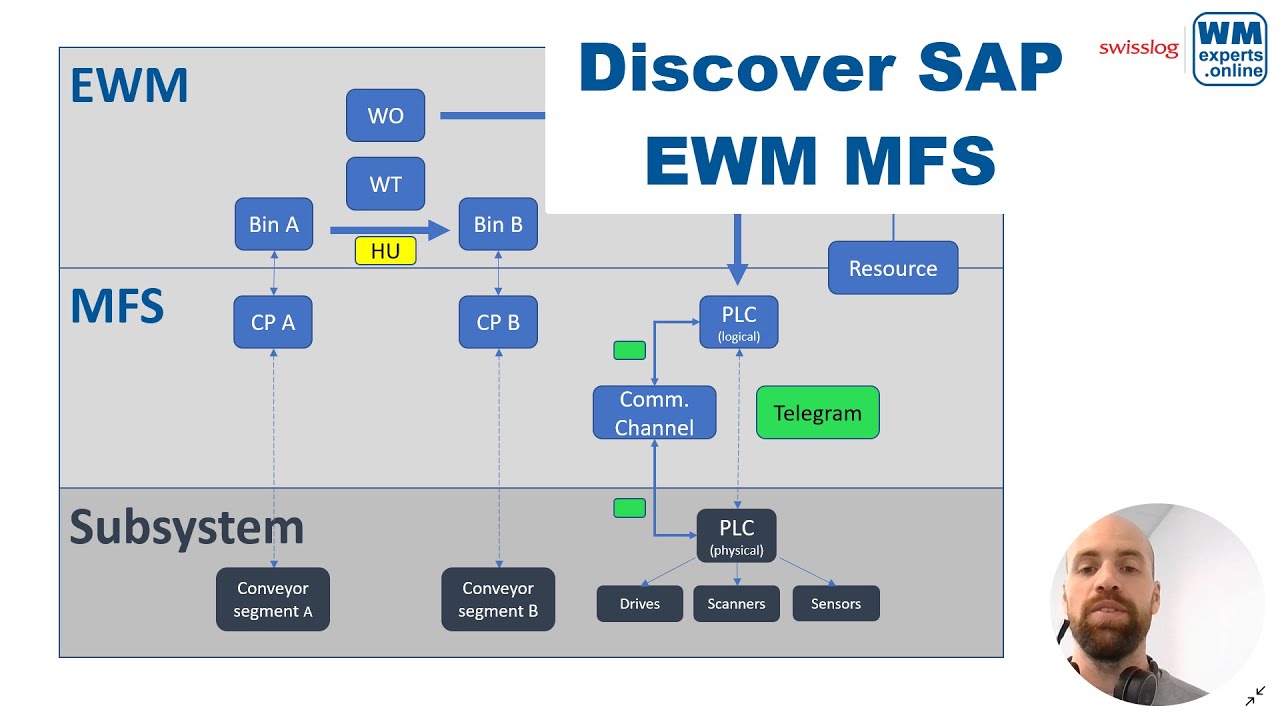

Discover SAP EWM MFS

The EWM-PLC integration

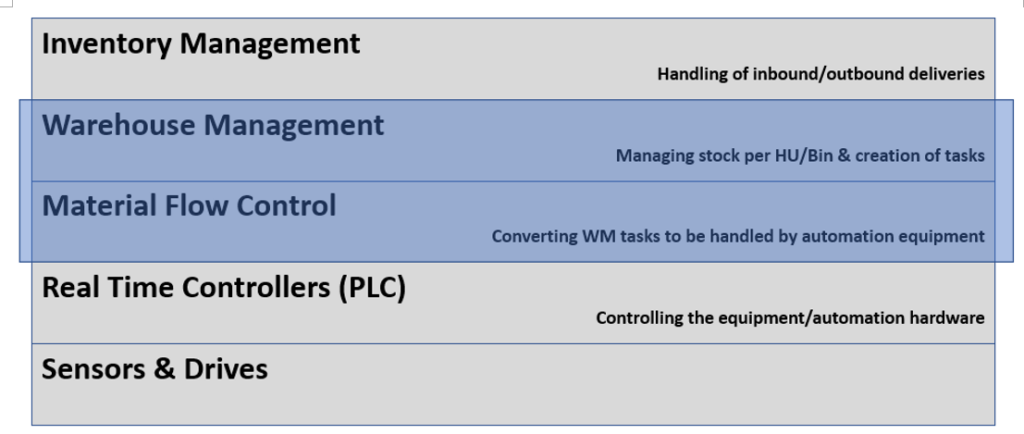

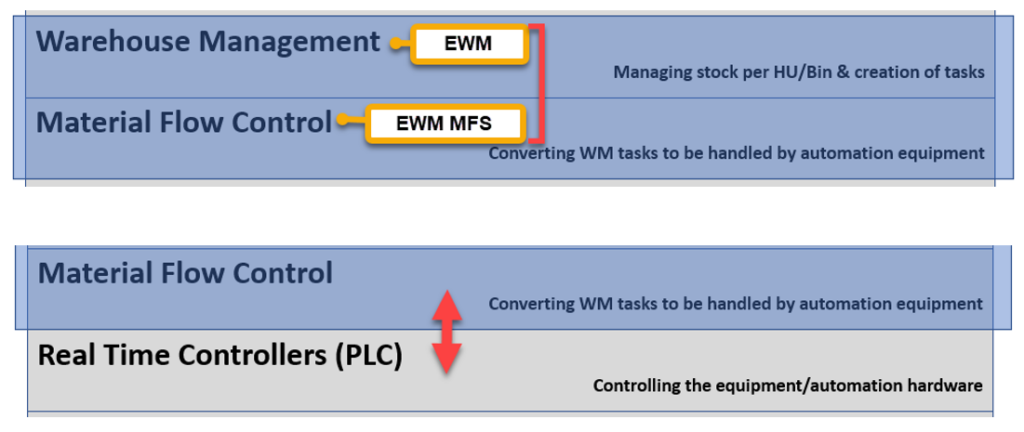

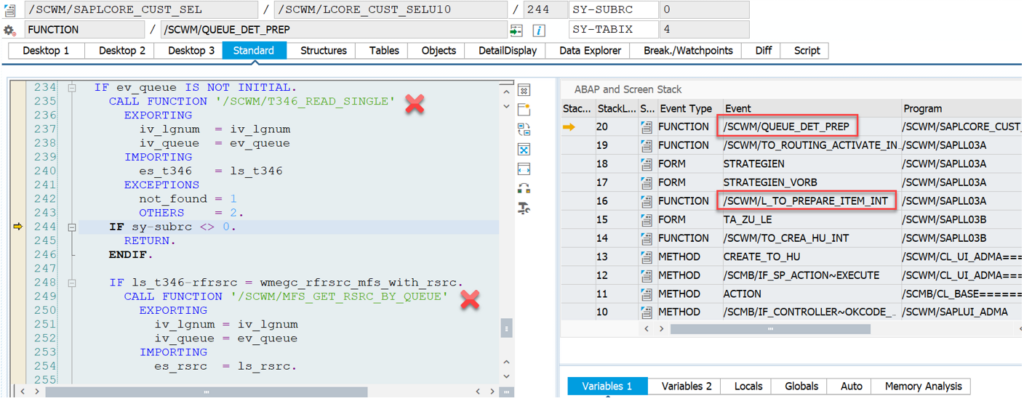

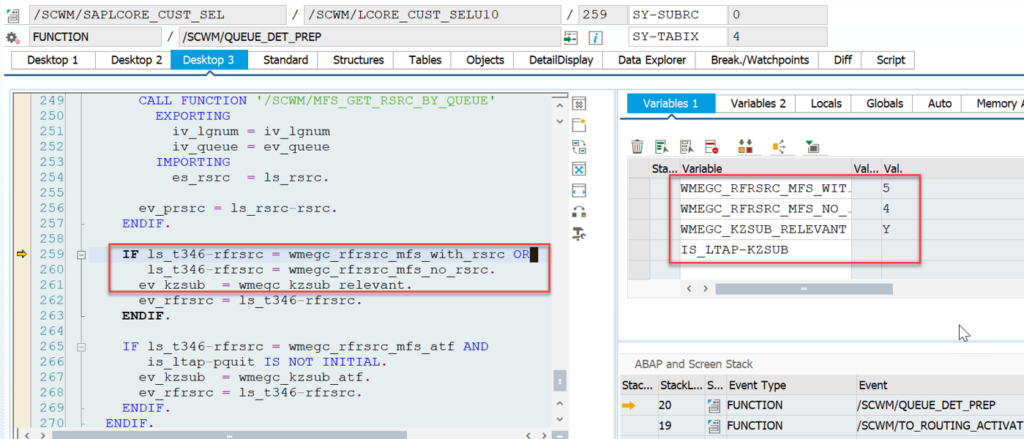

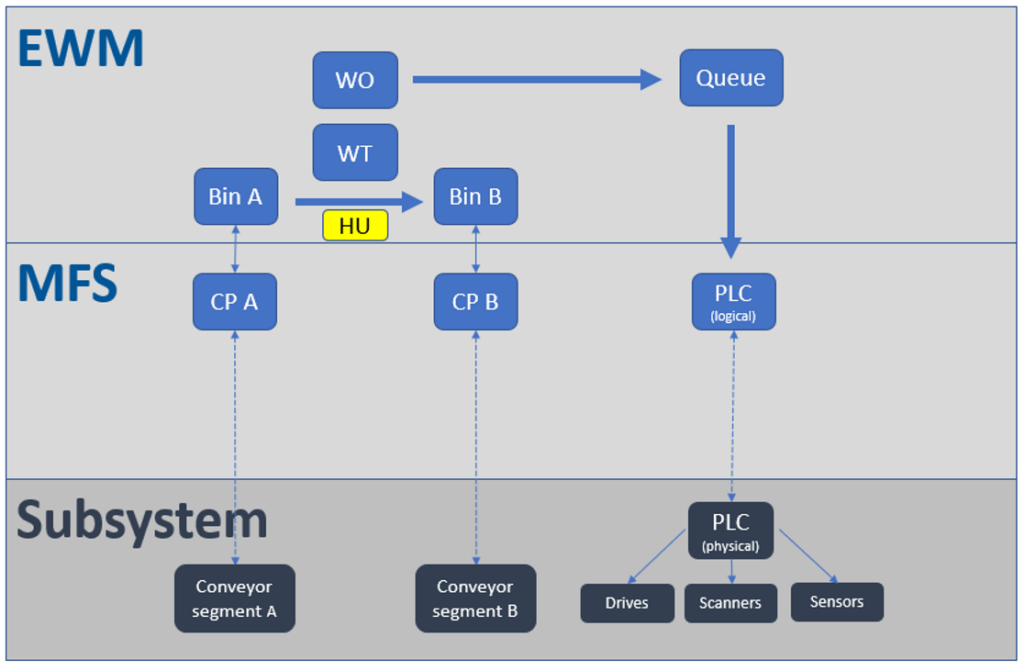

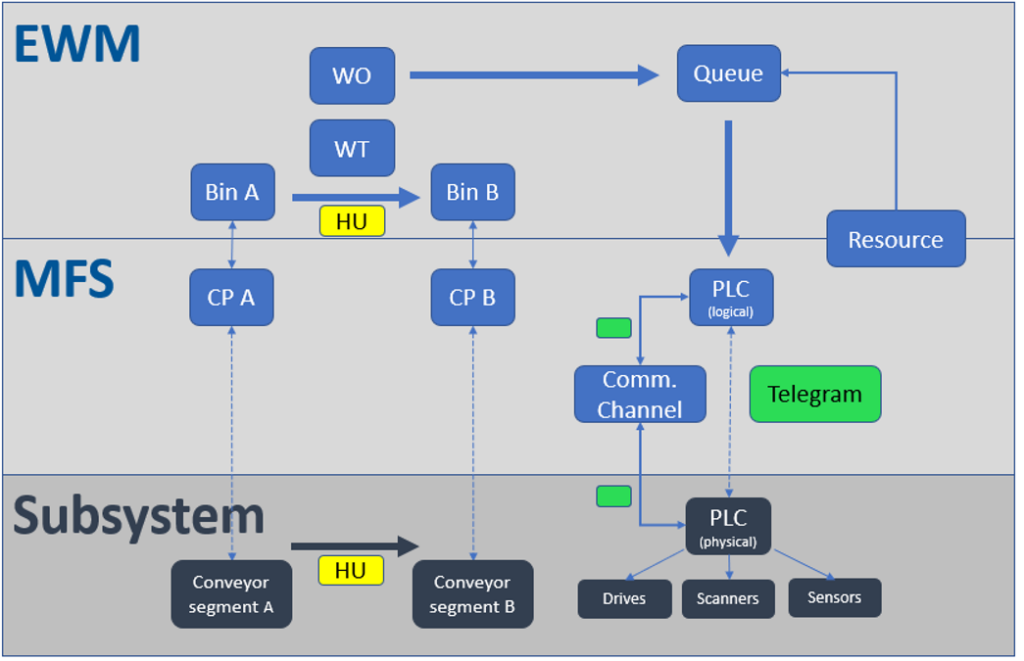

This blog is part of the series ‘SAP EWM meets Automation – Discover EWM MFS’ and gives you an introduction to the EWM PLC integration and the MFS component of EWM. In this context, we will look at the most important objects which are used to represent the physical material flow components in MFS. In addition to this I will explain on a high level how the MFS component integrates with the subsystem/PLC layer.

Note that we will not look into the details of the communication between EWM and a subsystem as such. This will be part of additional post which I will release during the next months.

Also note that we will be focusing on the approach for the PLC integration which EWM uses for slow-moving MFS environments which are controlled based on the layout-oriented storage control (LOSC). In this context we are working with warehouse task triggering and pushing for the communication with the PLC. Fast-moving environments like case conveyor operations can make use of EWMs Case Conveyor Routing logic which does not require warehouse tasks to be created in order to initiate a communication (telegram exchange) with the PLC. The latter is not in scope of this blog post but will be tackled in a separate one (once I find the time… :-)).

Agenda

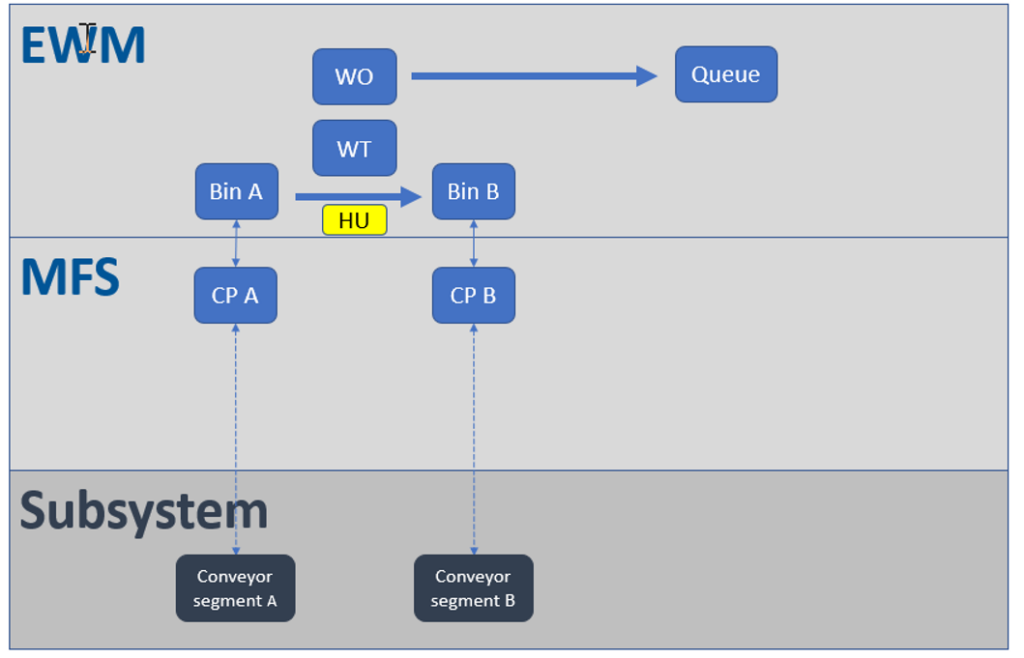

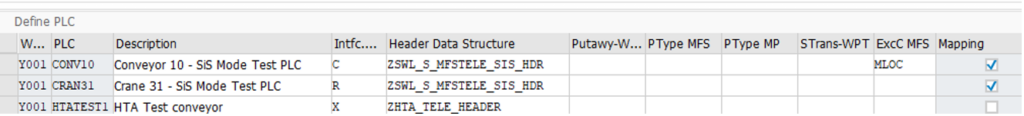

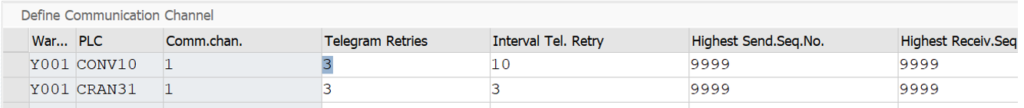

What are the most important objects that EWM uses to integrate its MFS component and to integrate with the PLC?

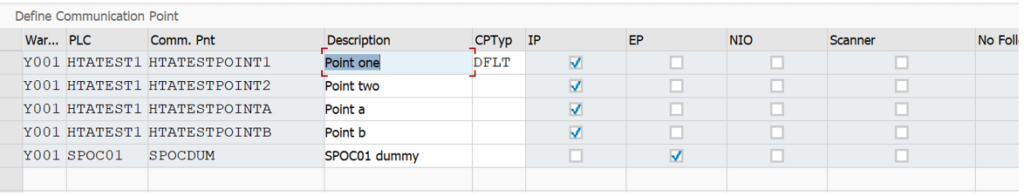

- Communication points

- Queues

- PLCs

- Communication Channels

- Resources

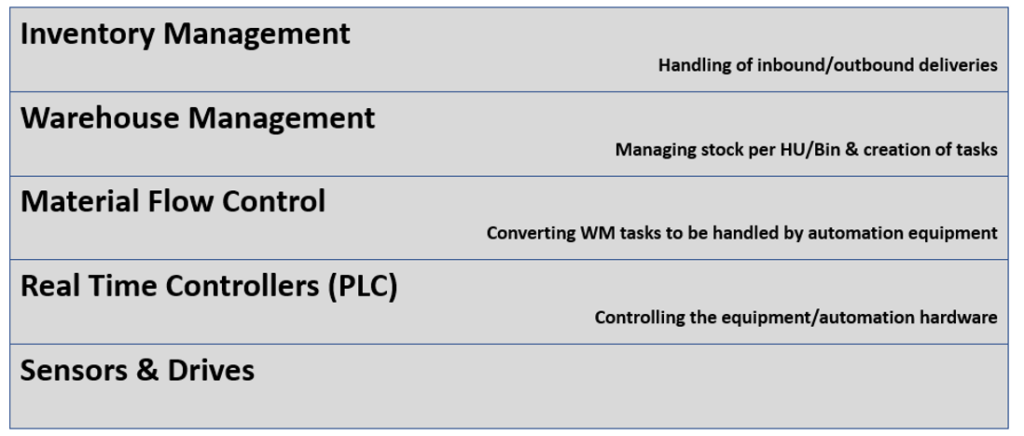

EWMs MFS components integrates with the PLC which in turn controls sensors and drives. Check this blog post in case you want to learn more about what a PLC is and what it does.

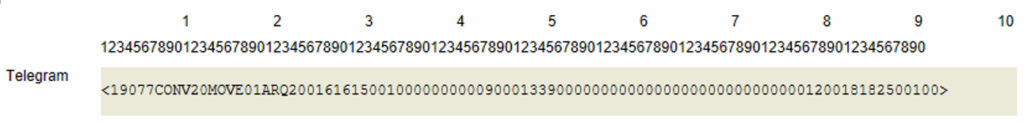

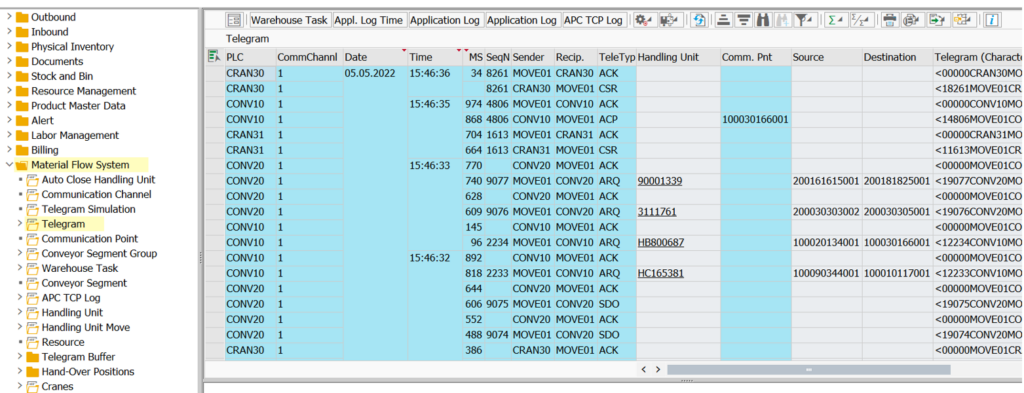

As part of this post we will tackle the integration of the MFS component within EWM on the one hand but also the connection between the MFS component and the PLC on the other hand.

WTs are communicated to PLCs if they are added to queues which are relevant for MFS (~ have the respective parameter for the operating environment and a PLC linked to it). That also means that the communication of warehouse tasks to the subsystems is invoked by the queue determination rules (customizing). Again note that we are talking about slow-moving MFS environments using the layout-oriented storage control for routing. Case Conveyor Routing as an alternative can invoke the communication with the PLC without creating warehouse tasks upfront. This concept is not in scope of this blog post though.

Summary

I hope you do feel a bit more comfortable now with the most important objects that EWM uses to integrate with its MFS component as well as with the subsystems (~ the actual hardware). Be aware that I skipped some details in order to avoid distraction and to highlight the important points. I might come back to the specialties and technical details as part of additional posts.

Before that happens, I will give you a step-by-step overview of the communication from EWM to the PLC and the other way around. I am working on this and will release the articles during the next months.

I hope this blog post provides value to you and you could learn something. Please feel free to subscribe to my blog updates or my youtube channel in case you want to be notified about new posts!