Discover SAP EWM MFS

What is SAP EWM MFS?

This blog is part of the series ‘SAP EWM meets Automation – Discover EWM MFS’. As with all posts of this series, the content provided here has been created in cooperation with the SAP EWM team at Swisslog. Feel free to visit their website in case you want to learn more about the services offered by Swisslog or to browse open positions within their EWM team!

This blog post is intended for those of you who never implemented an automated warehouse with EWM MFS or even never used SAP EWM before. I wrote this article as I noticed that some of my subscribers/readers are actually part of this group. This is not a problem at all but I thought it might be beneficial to induct those with a very simple post answering this apparently simple question (did not think of this when I started this series initially – otherwise that would have been the very first post).

You should indeed have a rough understanding about what a WMS (Warehouse Management System) is doing and that SAP EWM is such a system. But apart from this – I do not request any additional prior knowledge here.

My proposal –

This blog post exchanges 5 minutes of your life against the answer to the question ‘What is EWM MFS?’

Expect a short, compact and simple summary!

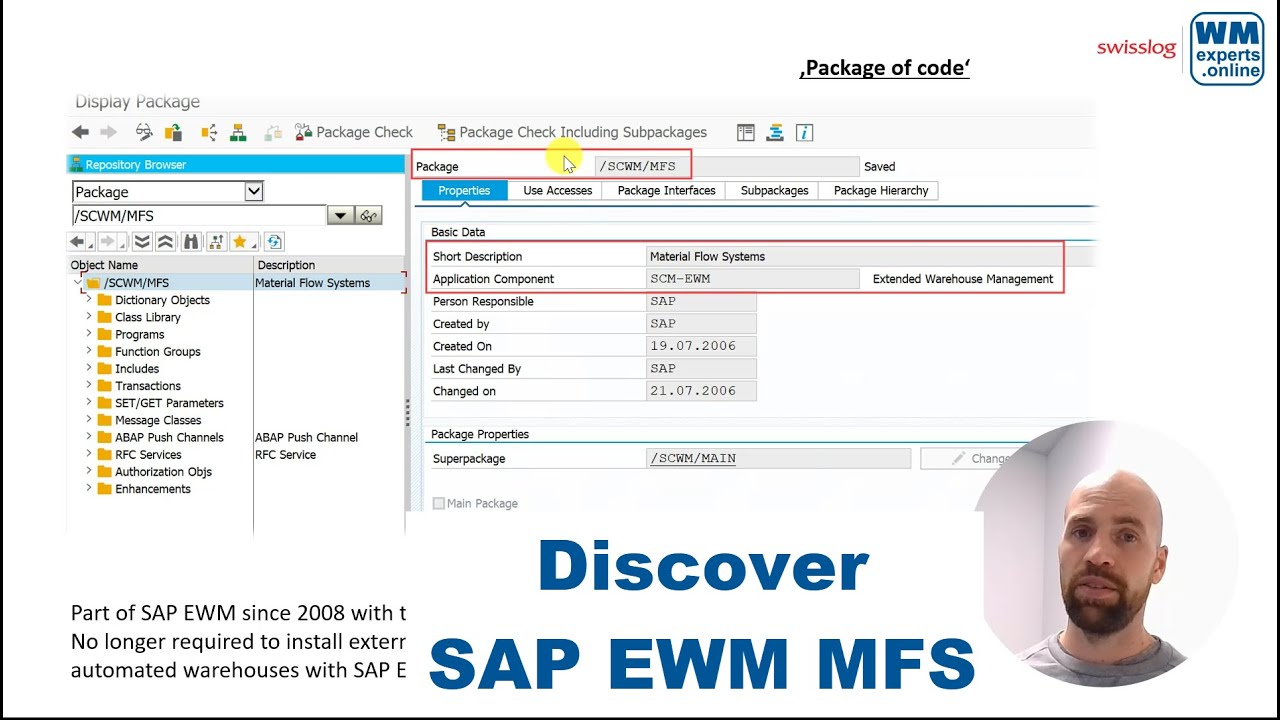

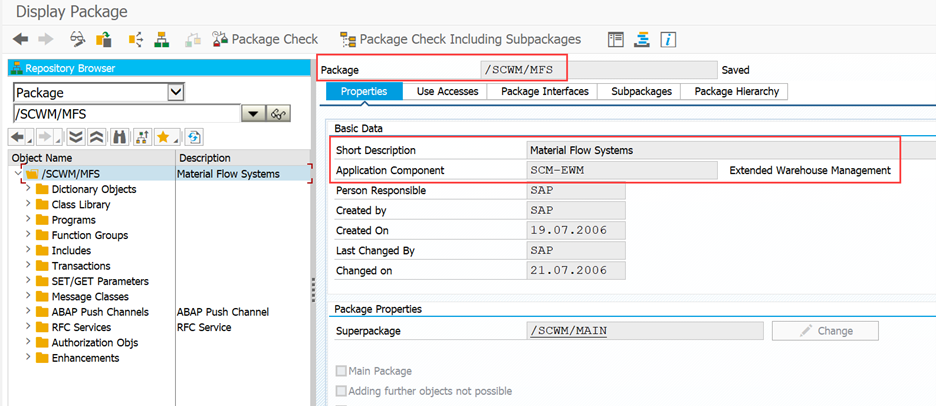

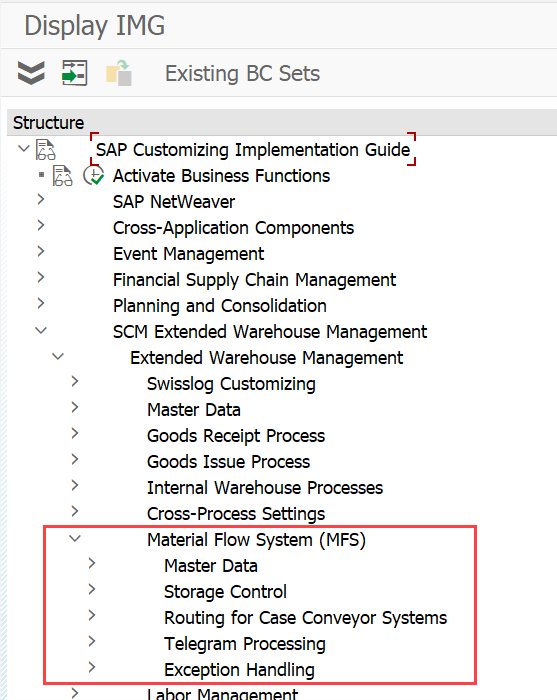

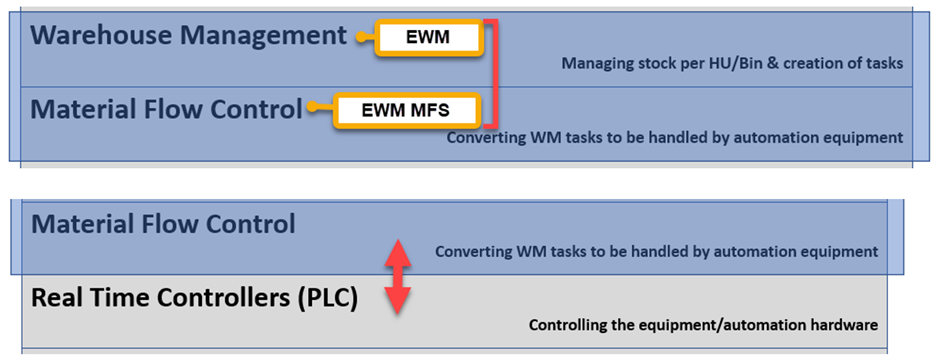

Technically, EWM MFS is a package of code sitting in SAP EWM which enables EWM to talk directly with different kind of automation equipment.

Let us break this into smaller pieces / keywords in order to understand it:

- Package of code

- Talk directly

- Automation equipment

We start with the last one to have something physical in mind right from the beginning –

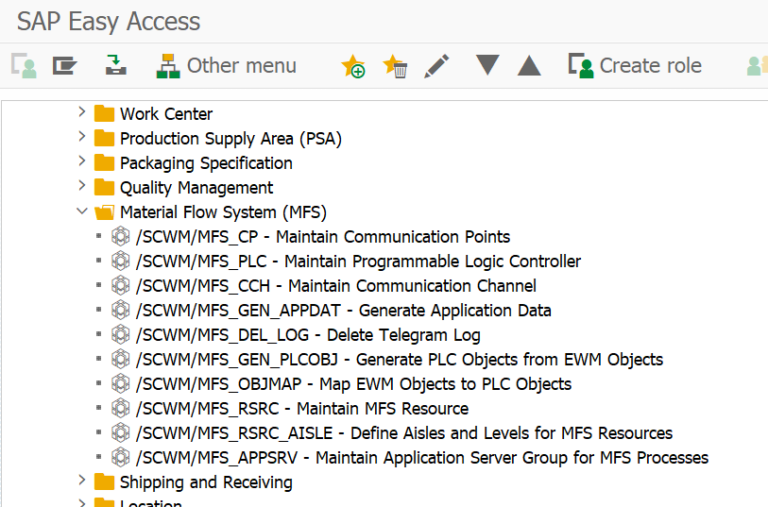

What is automation equipment in this context? That could basically be everything that moves without direct operator control within a warehouse and is controlled by a PLC (Programmable Logic Controller). So technically EWM talks to the PLC and not directly to the equipment (this is an important difference). Automation equipment in this context could be conveyors of all different kinds, Automated Storage and Retrieval Systems (ASRS) operated by cranes, Monorails and many more:

So this is the stuff that EWM MFS is talking to via the PLC (EWM > PLC > Automation Hardware).

It is realized by what I mentioned as package of code in my definition above. This package is part of SAP EWM since 2008 with the release of EWM 5.1. Post this release, it was no longer required to install external middleware or warehouse control units in order to run automated warehouses with SAP EWM (so you could actually communicate with PLCs and the automation hardware already before that but not without using an additional middleware or control unit in between > more details further below).

Last but not least, I explain what I have in mind when I say talk directly to automation equipment?

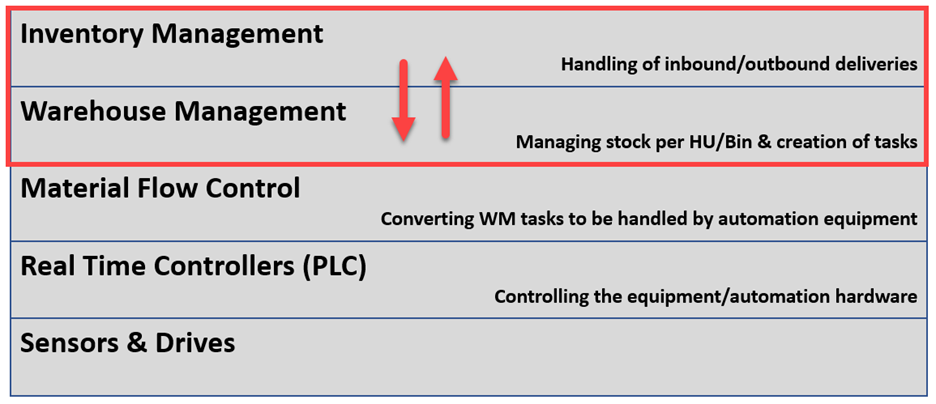

I provided a short hint already above, mentioning the ‘middleware’ or ‘control unit’. To make this more tangible, let us look at the warehouse automation layer model published via VDI standard 3962. EWM as our warehouse management system is sitting right under the inventory management system which is managing orders, creating deliveries and pushes those towards EWM:

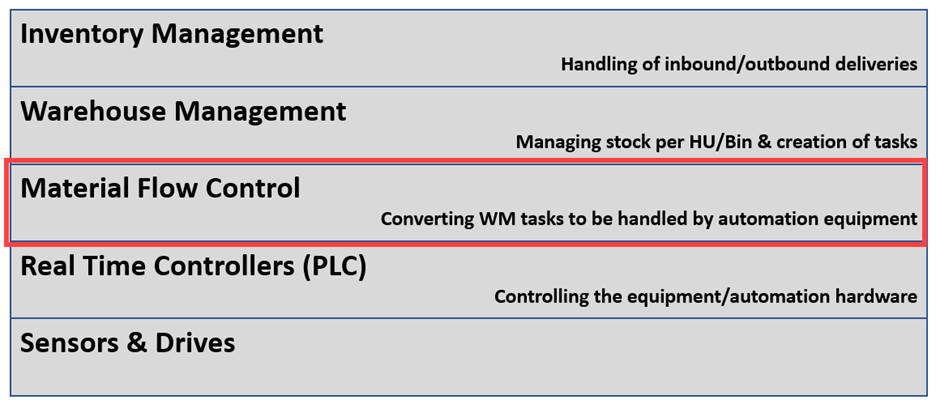

EWM – before the integration of its MFS component – was mainly managing stock per HU/storage bin and creating tasks against deliveries in order to move this stock into or out of the warehouse. In order to talk to automation equipment (programmable logic controllers to be precise again) it required an additional middleware (here shown as ‘Material flow control’ layer):

And what does it technically mean when I say ‘talking’ to automation equipment? At the end it is all about exchanging strings of data based on a pre-defined protocol, which helps to enable a stable communication and to interpret the data which is being exchanged. These data strings are what we call telegrams in the context of EWM MFS.

At this point we are on the edge of leaving the surface and digging into detail which was not the intention of this blog post. I hope the question ‘What is EWM MFS?’ has been answered for you in an easy & understandable way.

For those who are interested in further details I can recommend these blogs/videos:

- Check this blog post in order to understand what a PLC is and what it is doing in the context of automation with EWM MFS.

- Check this blog post in order to understand the role of important objects in SAP EWM MFS.

- Check this blog post in order to understand how EWM MFS talks to the PLC.

I hope this blog post provides value to you and you could learn something. Please feel free to subscribe to my blog updates or my youtube channel in case you want to be notified about new posts!